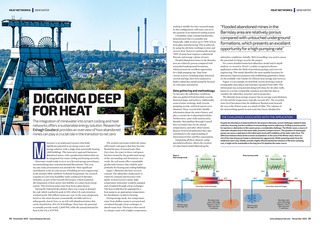

HEAT NETWORKS | MINEWATER DIGGING DEEP FOR HEAT The integration of minewater into smart cooling and heat networks offers a sustainable energy solution. Researcher Eshagh Goudarzi provides an overview of how abandoned mines can play a crucial role in the transition to net zero M inewater is an underused resource that holds significant potential as an energy source and storage solution, with a single mine potentially heating 1,800 buildings. This innovative approach harnesses abandoned mines, with a geothermal solution that can be integrated into smart cooling and heating networks. Minewater stands ready to serve as a thermal storage powerhouse, accommodating inter-seasonal demand fluctuations. This year, my case study presentation was awarded the Most significant contribution to the art and science of building services engineering at the annual CIBSE ASHRAE Technical Symposium. My research expands on a previous feasibility study conducted in Barnsley, Yorkshire, as part of the GreenSCIES project, which examined the integration of heat, power and mobility in a smart local energy system. This involved using waste heat from a glass factory. During the Industrial Revolution, there was a surge in demand for coal, which reached its peak in 1913, when UK coal extraction reached nearly 290 million tonnes per year. As the years progressed, however, the mines became economically unviable and were subsequently closed. Now, we are left with abandoned mines that can be found below 25% of UK buildings. These have the potential to annually provide nearly 2,200TWh, while the annual demand for heat in the UK is 475TWh. 34 November 2023 www.cibsejournal.com The worked coal seams within the mines still contain void spaces that have become flooded because of natural water flow. Over time, the water in these void spaces has been heated by the geothermal energy of the surrounding rock formations. As a result, the coal seams offer a sustainable geothermal resource that could be used primarily for heating and cooling buildings. Figure 1 illustrates the heat recovery concept. The subsurface temperature is relatively constant and increases with depth. In heat recovery mode, hightemperature minewater would be pumped and circulated through a heat exchanger. The heat would then be upgraded by a heat pump to an appropriate temperature for distribution via district heating. During storage mode, low-temperature water from shallow seams is extracted and circulated through a heat exchanger to absorb waste heat. This heat is then stored in a deeper seam with a higher temperature,