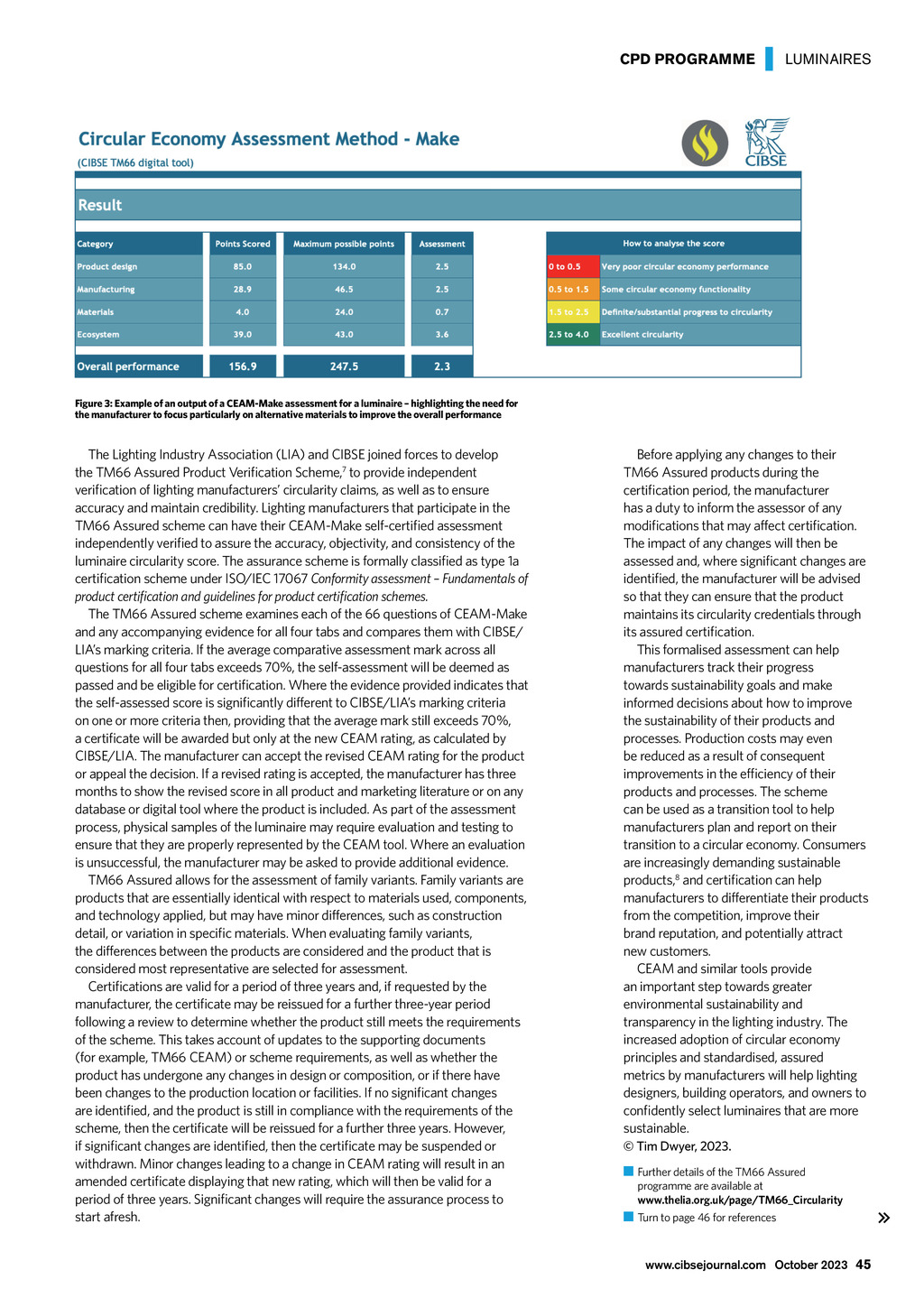

CPD PROGRAMME | LUMINAIRES embodied carbon of MEP products where a manufacturer has not already developed a BS EN 15804:2012+A2:20194-compliant environmental product declaration (EPD) for their product. The embodied carbon calculations in CIBSE TM66 Creating a circular economy in the lighting industry builds on the methodology outlined in CIBSE TM65. It provides a background to circular economy principles, and sets out the drivers and barriers specifically for lighting products. A common benchmarking tool is introduced that aims to overcome the diversity of results from the individual methods that are presented by lighting manufacturers employing their own bespoke techniques, which make it challenging to compare claims of sustainability across the industry. TM66 is designed to balance complexity with effectiveness and usability but is very reliant on the users level of knowledge, and their interpretation of the supply and manufacturing supply chains for their product. Case studies are included that demonstrate how some of the principles of a circular economy have been successfully implemented by lighting manufacturers. The Circular Economy Assessment Method (CEAM) illustrated in TM66 employs accompanying Excel spreadsheet tools to steer manufacturers towards improved product circularity, as well as providing specifiers and clients with an understanding of the questions they need to ask of their suppliers. The tool, CEAM-Make, employs an Excel spreadsheet comprising 66 questions under four tabs product design; manufacturing; materials; and supporting ecosystem to assess a luminaire in terms of its circular economy performance. By adding the specific answers to the questions, products are given a rating of zero to four, with the spreadsheet tool allowing iterative inputs to encourage and enable manufacturers to improve the rating. The zero baseline for a product indicates very poor circular economy performance, with the intent of the tool being to encourage and enable products and support ecosystems that score three or four, indicating excellent circularity. The CEAM-Make spreadsheet, as shown in the example in Figure 3, provides a final rating in this illustrated case, highlighting that the manufacturer needs to particularly reconsider some of the materials that are being employed in order to improve the circularity credentials of the product. Accurate completion of CEAM-Make relies on the input of fair and reasonable values backed by hard evidence, with the sheets guidance notes warning that there is no 44 October 2023 www.cibsejournal.com PINNING DOWN LUMINAIRE COMPONENT DATA The recent case study5 by Albu et al explored the lifecycle assessment (LCA) of an example LED suspended luminaire (as shown in Figure 2) designed for use in office, education, residential and retail applications. This comprised an aluminium LED polyurethane powder-coated housing, a driver power supply with electric protection, an LED linear module with electronic control system, a polycarbonate opal diffuser, and various connections and fixings (electrical cables, connection plugs, and screws). For a seemingly simple luminaire there is a reasonably extensive schedule of components, as shown in Table 1, many being sourced at some distance from the final manufacturing location. Albu and his co-authors employed proprietary software that draws on many embodied carbon resources (including the freely downloadable ICE database6) to undertake the LCA. Without detailed knowledge of the manufacturing process of the many specific components, it can be difficult to determine the level of confidence in the provenance and reliability of data for some components. Reasoned, and evidenced, judgments will be required to assess the product data, especially the questions about manufacturing and materials on the CEAM-Make spreadsheet. A significant amount of investigation and evidence-gathering may be necessary to maintain a credible process. However, this can be avoided if the components themselves have an accredited EPD or similar. Once the initial investigation has been conducted for a product, it is likely that the same data may be repurposed by the manufacturer for other luminaires in the product family. Figure 2: Simple example of suspended LED luminaire Raw material Aluminium extruded profile (body) Quantity (kg) 1.93 Transport distance (km) 193 Epoxy powder paint 0.04 1,196 Aluminium extruded profile (fixing clips) 0.46 193 Polycarbonate cable connector 2p + n 0.005 542 ABS cable gland 0.005 19 Copper electric cable FY 0.5mm 0.05 11 Copper electric ground wire 0.1 11 Copper electric cable 3x0.5mm 0.01 11 Polycarbonate opal dispenser 0.13 1,881 Steel screws M4 0.01 591 ABS plastic taps 0.08 19 ABS plastic clips 0.08 19 LED module 0.07 1,690 LED driver 0.18 1,690 Driver selector plug 0.001 1,690 Paper adhesive label 50x32mm 0.02 12 Table 1: Schedule of components in an example LED luminaire wishful thinking or generalised statements allowed evidence must be specific and supported (see the boxout Pinning down luminaire component data). The end result of the process is a self-certified metric of luminaire circularity. There is an additional, associated spreadsheet that provides a short-form triage tool for a designer, specifier or engineer CEAM-Specify. The four tabs provided in Make are collapsed into one in Specify, allowing the quick comparison of two or more products. The CEAM has been created to improve sustainability in the lighting industry and, as such, should be used to assist in the accurate assessment of circular economy performance. It is a rigorous assessment tool that helps manufacturers to identify and improve the environmental impacts of their products. This can give manufacturers greater confidence that their products are truly sustainable and that they are meeting the needs of their customers. The tool is not intended to be used to game the process in order to misleadingly inflate the circular economy performance scores.