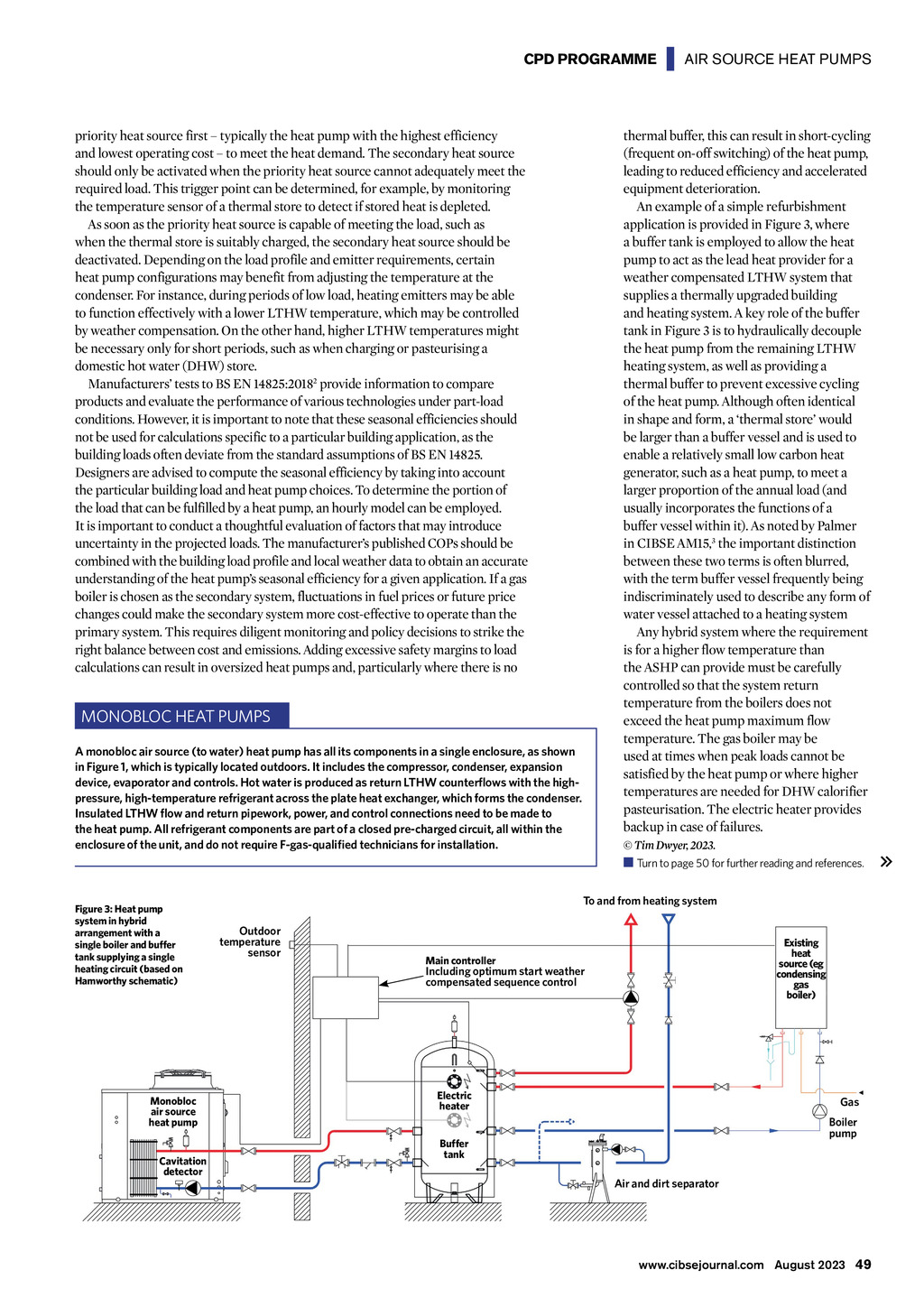

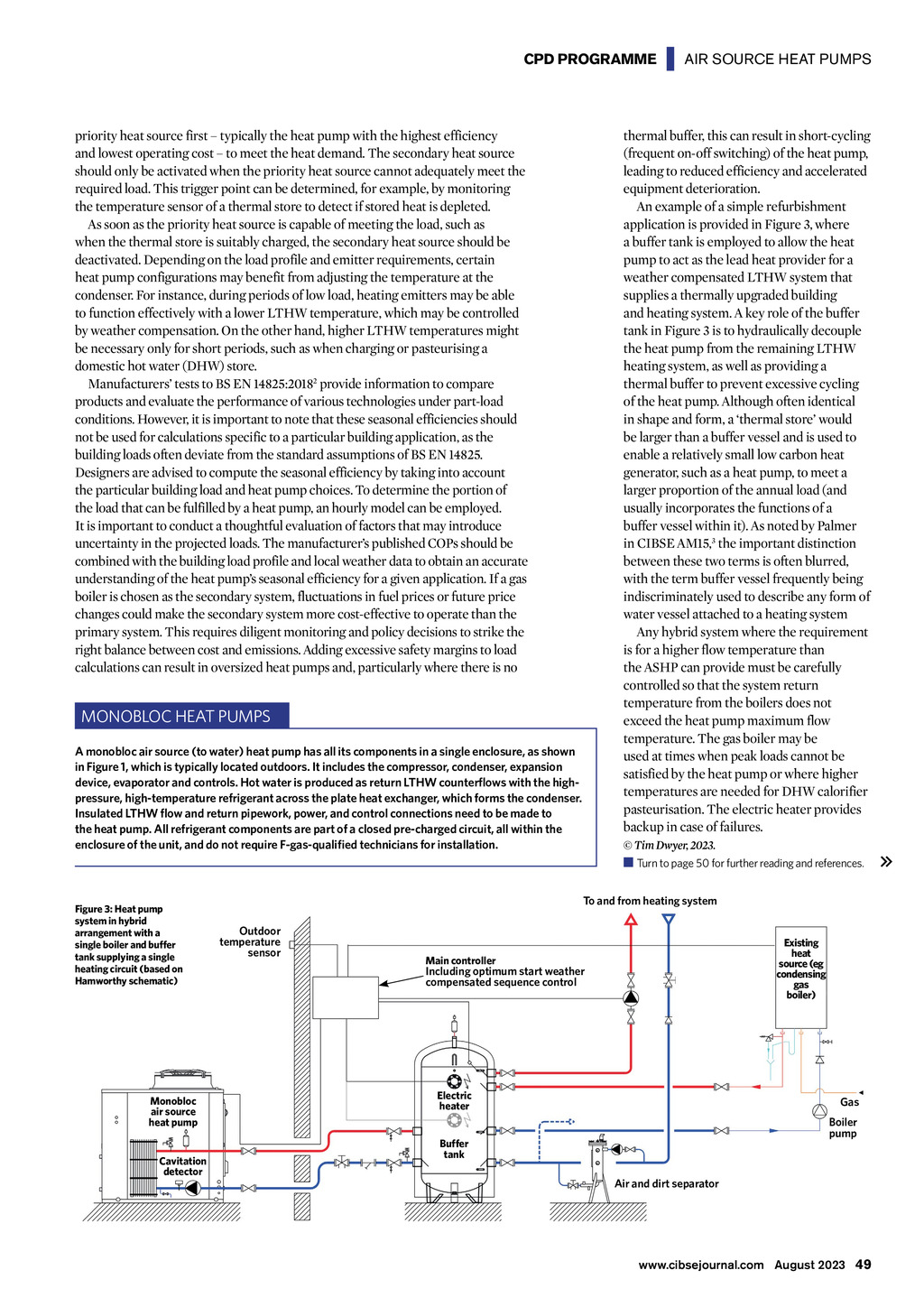

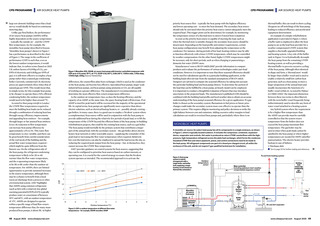

| AIR SOURCE HEAT PUMPS large non-domestic buildings notes that a load survey would ideally be based on continuous metering data. Unlike gas-fired boilers, the performance of air source heat pumps (ASHPs) will be highly dependent on the source temperature typically the outside air and the LTHW flow temperature. So, for example, the monobloc heat pump (described in boxout, Monobloc heat pumps) shown in Figure 1 has a performance as described in the chart of Figure 2. The range in the coefficient of performance (COP) is such that, even at the lowest outdoor temperatures, it would indicate that, in carbon terms (based on 2022 UK carbon factors of 0.193kg of CO2e per kWh of electricity and 0.183kg per kWh of gas), it is still more effective to employ a heat pump rather than a natural gas condensing boiler. Currently, commercial UK electricity prices are approximately three times that of natural gas per kWh. This would mean that, in simple terms, for this example heat pump to be cheaper to operate than a 92%-efficient condensing boiler, the outdoor temperature would need to be higher than around 7C. As noted in Heat pump retrofit in London,1 the LTHW flow temperatures required to meet the building heat loads can be reduced through a combination of reducing heat loss through energy efficiency improvements and upgrading heat emitters for example, through larger or fan-assisted heat emitters. Every 1K reduction in flow temperature can increase heat pump efficiency by approximately 1.5% to 3%. This water flow temperature is a key variable, and there can be great benefit from careful consideration of the real needs of the building and the actual flow water temperature required which might be quite different from the historic use. On the refrigeration side of the heat pump, the refrigerant condensing temperature is likely to be 2K to 4K warmer than the flow water temperature, and the evaporating temperature likely to be 5K to 8K cooler than the outdoor air temperature. For ASHPs, there are limited opportunities to provide sustained increases in the source temperature, although there may be a chance to benefit from a local warm air discharge from a process or other environmental system. AM17 highlights that ASHPs using common refrigerants (such as R32 with a relatively low global warming potential [GWP] of 675) typically produce water at a maximum of between 55C and 60C, with an outdoor temperature of -5C. ASHPs are designed to operate within a specific range of load flow-return temperature difference that, for many massproduced heat pumps, is about 5K. At higher 48 August 2023 www.cibsejournal.com Figure 1: Monobloc R32, 50kW, air source heat pump with inverter-controlled compressor with COP up to 4.11@water 35C, air 7C, SCOP 4.16@35C, 3.08@55C. 1.920m wide, 1.110m deep, 1.920m high, 535kg (Source: Hamworthy) differences, the counterflow plate heat exchanger, which is used as the condenser in the heat pump, can become less effective. Specialised heat pumps, larger-scale industrial heat pumps, and heat pumps using ammonia or CO2 are all capable of working at a greater difference. The manufacturers recommendations will determine the most effective flow-return temperature difference. As the outdoor air temperature rises, so does the heating efficiency and the capacity of an ASHP; at the same time, the space-heating loads will decrease. If an ASHP is sized for peak load it will be oversized for the majority of the operational life. In capital terms, heat pumps are significantly more expensive than direct electric solutions, such as electrical backup heaters, or possibly already existing gas boilers. In many cases, there is a good case to employ a bivalent system where a complementary heat source will be used in conjunction with the heat pump to provide additional heat during the relatively few periods of peak load, or to lift the temperature of the LTHW beyond the efficient limits of the heat pump. In building refurbishment projects, this could be the existing heat source, such as a gas boiler. The heat pump would normally be the primary system that contributes a larger part of the annual load, with the secondary system the gas boiler, direct electric heater, heat network or other renewable source supplying the remainder of the peak load or increasing the flow water temperature when required. Relatively low-cost thermal stores can also be employed to spread the load across the day, so reducing the required peak output from the heat pump but, in themselves, they cannot increase the LTHW flow temperature. AM17 provides guidance on control systems for heat sources, suggesting that they can be configured to prioritise heat sources based on carbon intensity or operating cost. It is crucial for the control strategy to ensure that the bivalent system operates as intended. The recommended approach is to activate the 4.5 4 55oC 45oC 35oC 3.5 3 COP CPD PROGRAMME 2.5 2 1.5 1 -8 -6 -4 -2 0 Outdoor temperature (oC) Figure 2: COP vs outdoor temperature at different flow water temperatures for example, 50kW monobloc ASHP 2 4 6 8