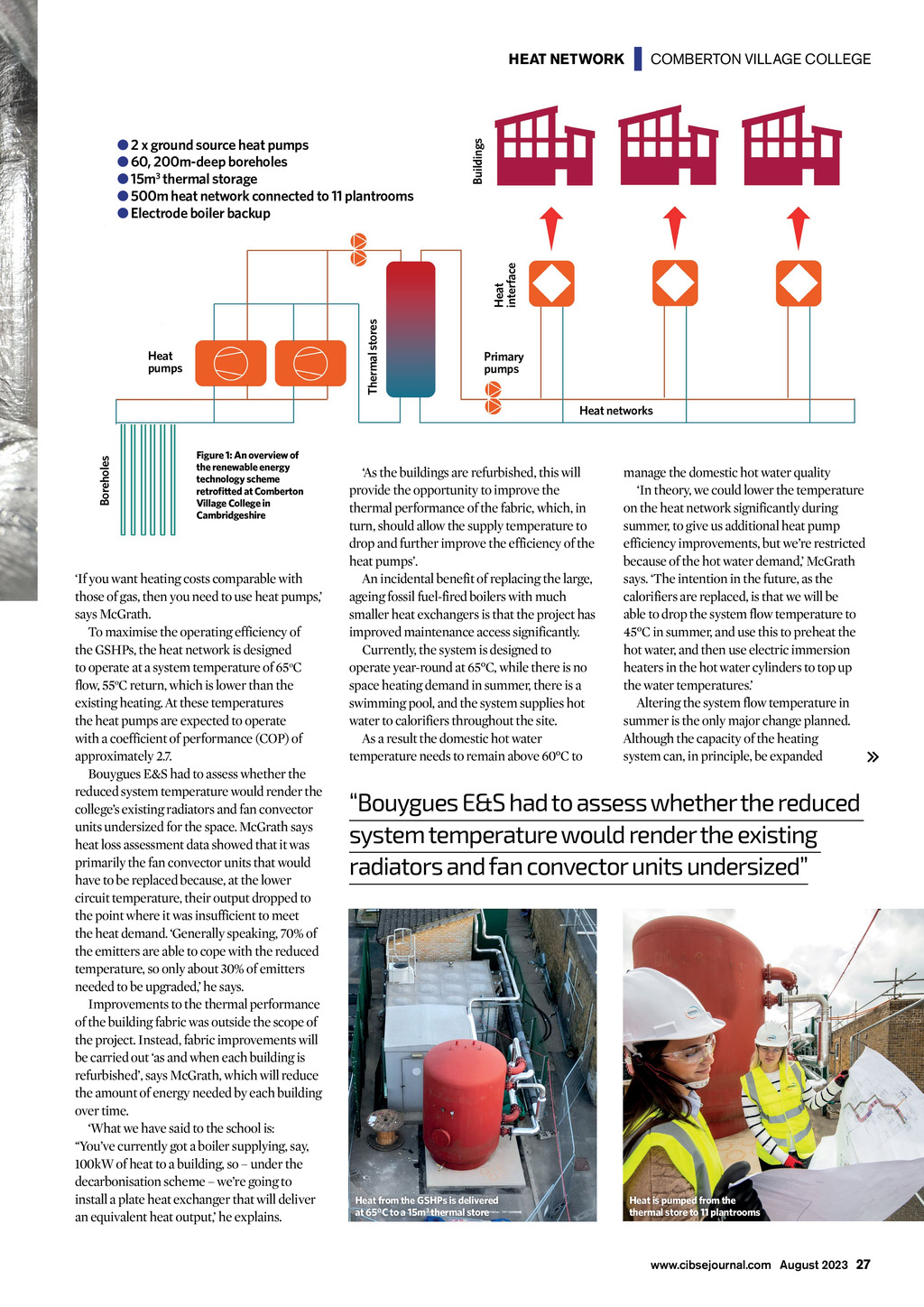

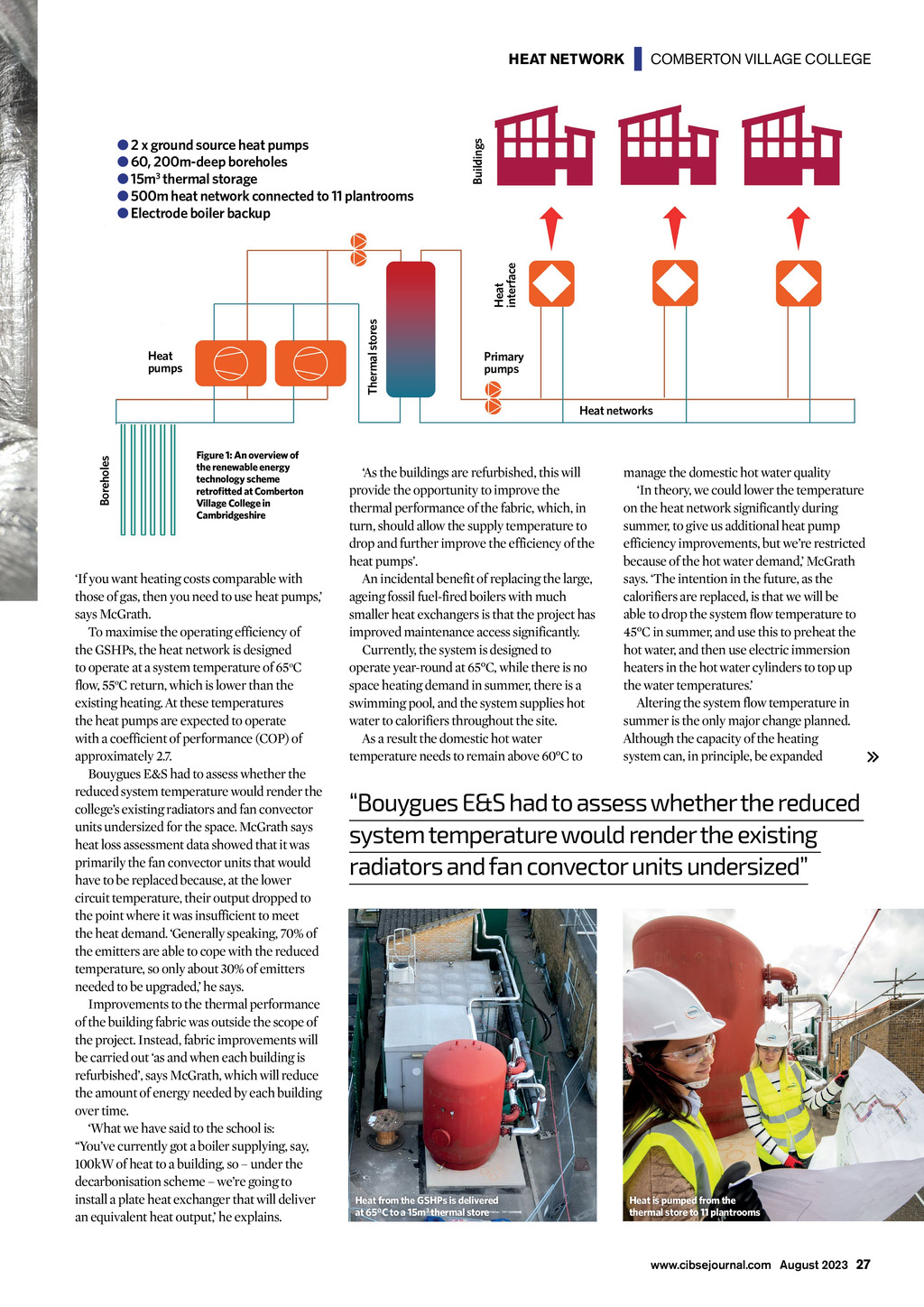

HEAT NETWORK | COMBERTON VILLAGE COLLEGE detailed design for the heat network was to make an assessment of the colleges peak heat demand. All we had to go on was the number of boilers, some of which had known operating efficiencies, and incomplete sets of fuel oil and LPG delivery notes, says McGrath. To try to quantify the peak heat demand, external consultants were employed to undertake a heat loss assessment for each of the colleges buildings. By combining this information and the fuel consumption data, a notional peak demand of 705kW was estimated. However, when it came to sizing the system, because of the uncertainty about the accuracy of the peak heating, and to increase the system resilience, the system was sized based on two 500kW Carrier ground source heat pumps (GSHPs), providing a total peak output of 1,000kW. These deliver heat at 65oC to a 15m3 buffer tank that smooths out the fluctuation in demand and allows the heat pumps to operate at their optimum setpoint. Hot water is then pumped from the thermal store around the campus to 11 individual plantrooms through insulated pipes, which are either buried or attached to buildings. As an additional contingency, an electrode boiler has been installed, which has the capacity to meet the peak demand and can provide top-up heat as and when required, such as if a heat pump is out of service. The heat pumps draw heat from ground loops contained in 60 boreholes, each 200m deep, located beneath three of the colleges car parks: 30 boreholes in one, 18 in another, and 12 in another. The boreholes are spaced at one per 9m2. One of the biggest challenges was installing boreholes on a live site where parking is at a premium, says McGrath. To mitigate this, The two 500kW ground source heat pumps New pipework installed for the heat network we spread them over the various car parks and phased the installation to minimise disruption to parking. This was a real success for the project and wouldnt have been possible without the close relationships developed between the client, design team and project managers. Bouygues E&S did consider air source instead of ground source, but the same issues of a lack of space and concern about noise from the condenser fans made this impractical. It also considered other heating options, including biomass and direct electric, which would decarbonise the college over time as the Grid decarbonises. www.jung-pumps.co.uk 0118 9821 555 Every time you specify a DrainMajor Tank, we will donate 5 to the Rainforest Trust. Tank Construction Polyethylene DrainMajor Wastewater Pumping System 26 August 2023 www.cibsejournal.com Email davidj@pumptechnology.co.uk so that we can donate on your behalf Specify pumping systems with recyclable tanks to support the environment!