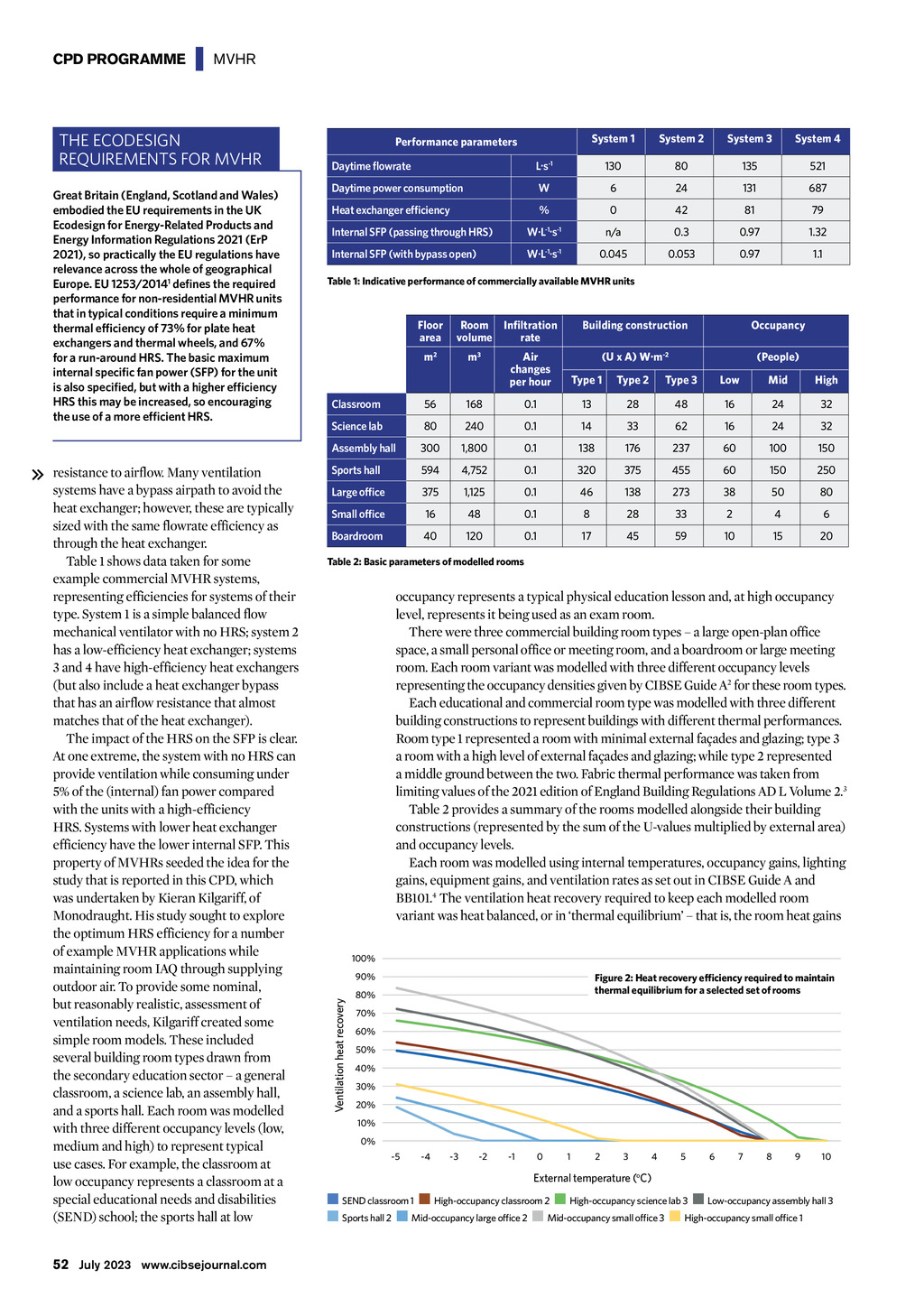

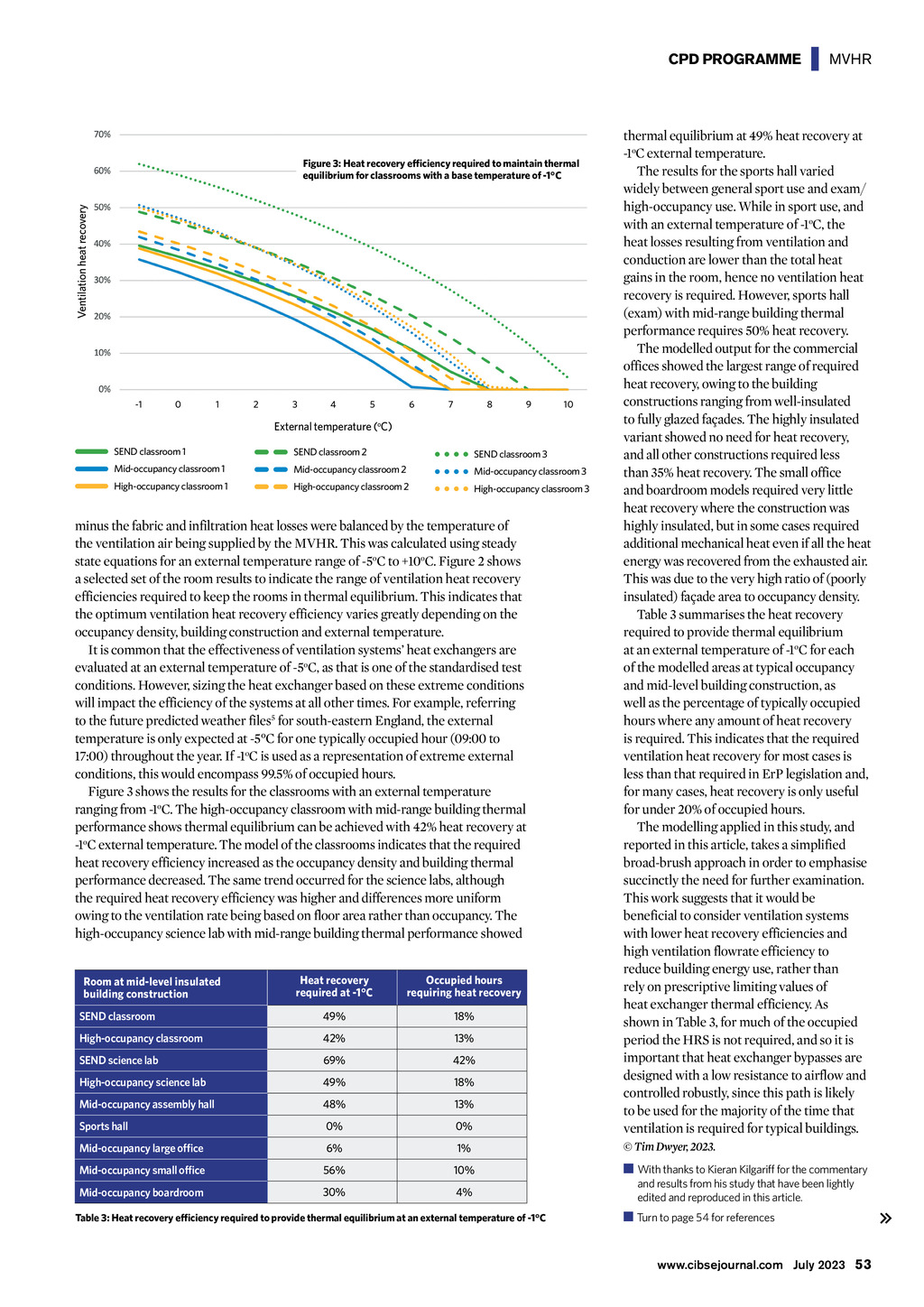

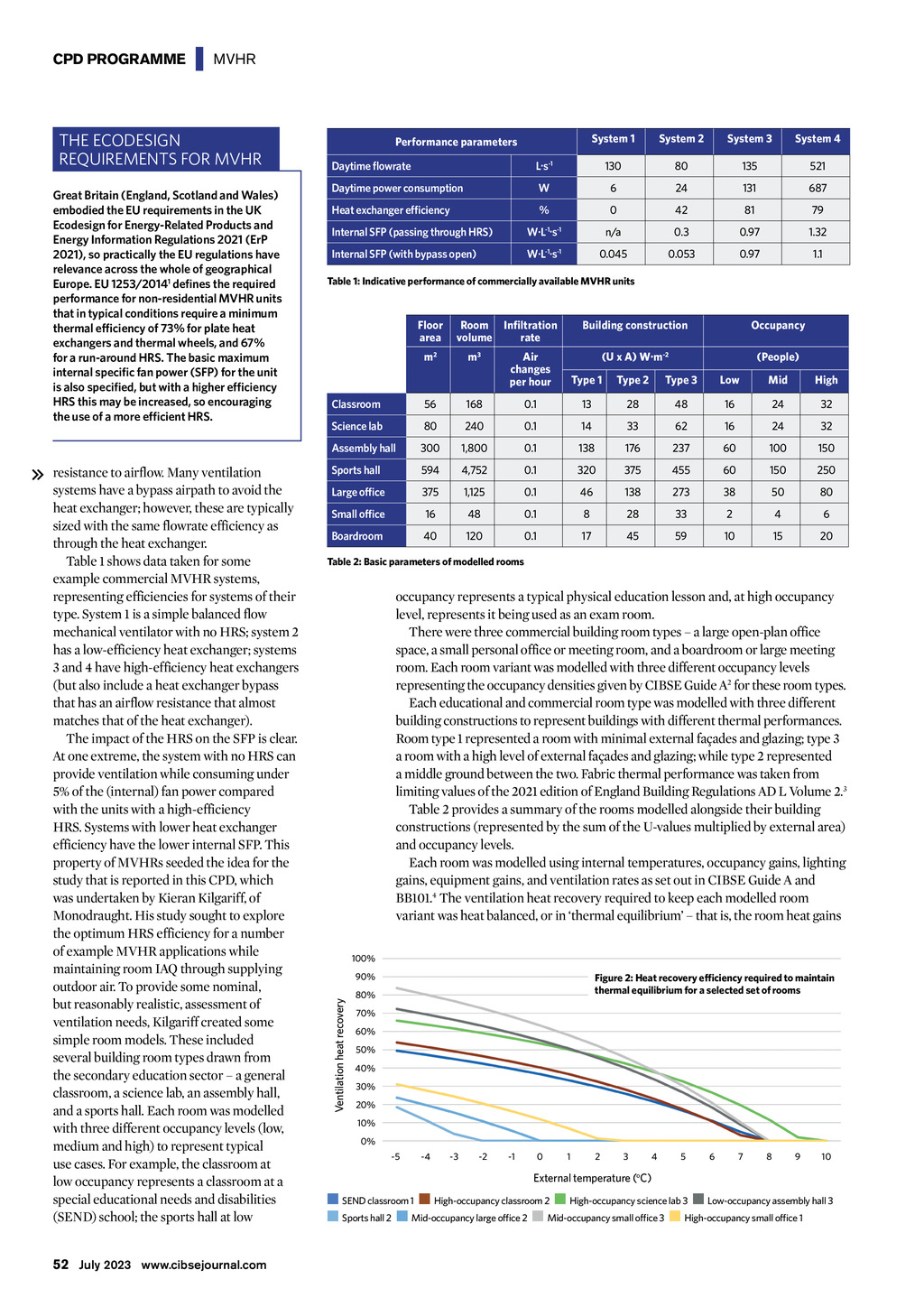

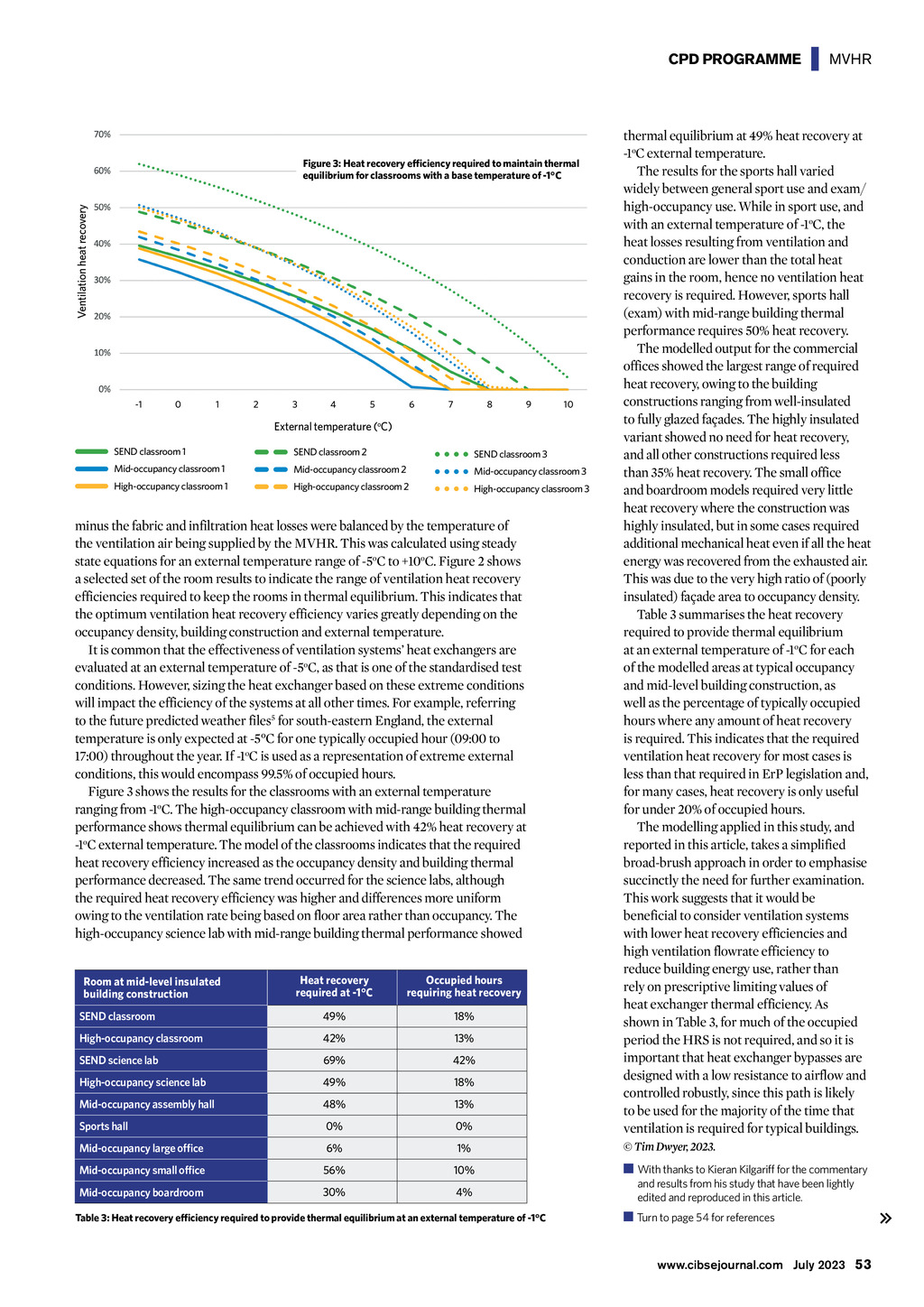

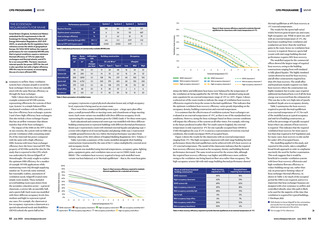

| MVHR THE ECODESIGN REQUIREMENTS FOR MVHR Great Britain (England, Scotland and Wales) embodied the EU requirements in the UK Ecodesign for Energy-Related Products and Energy Information Regulations 2021 (ErP 2021), so practically the EU regulations have relevance across the whole of geographical Europe. EU 1253/20141 defines the required performance for non-residential MVHR units that in typical conditions require a minimum thermal efficiency of 73% for plate heat exchangers and thermal wheels, and 67% for a run-around HRS. The basic maximum internal specific fan power (SFP) for the unit is also specified, but with a higher efficiency HRS this may be increased, so encouraging the use of a more efficient HRS. resistance to airflow. Many ventilation systems have a bypass airpath to avoid the heat exchanger; however, these are typically sized with the same flowrate efficiency as through the heat exchanger. Table 1 shows data taken for some example commercial MVHR systems, representing efficiencies for systems of their type. System 1 is a simple balanced flow mechanical ventilator with no HRS; system 2 has a low-efficiency heat exchanger; systems 3 and 4 have high-efficiency heat exchangers (but also include a heat exchanger bypass that has an airflow resistance that almost matches that of the heat exchanger). The impact of the HRS on the SFP is clear. At one extreme, the system with no HRS can provide ventilation while consuming under 5% of the (internal) fan power compared with the units with a high-efficiency HRS. Systems with lower heat exchanger efficiency have the lower internal SFP. This property of MVHRs seeded the idea for the study that is reported in this CPD, which was undertaken by Kieran Kilgariff, of Monodraught. His study sought to explore the optimum HRS efficiency for a number of example MVHR applications while maintaining room IAQ through supplying outdoor air. To provide some nominal, but reasonably realistic, assessment of ventilation needs, Kilgariff created some simple room models. These included several building room types drawn from the secondary education sector a general classroom, a science lab, an assembly hall, and a sports hall. Each room was modelled with three different occupancy levels (low, medium and high) to represent typical use cases. For example, the classroom at low occupancy represents a classroom at a special educational needs and disabilities (SEND) school; the sports hall at low 52 July 2023 www.cibsejournal.com Performance parameters System 1 System 2 System 3 System 4 Daytime flowrate L.s-1 130 80 135 521 Daytime power consumption W 6 24 131 687 % 0 42 81 79 Internal SFP (passing through HRS) W.L-1.s-1 n/a 0.3 0.97 1.32 Internal SFP (with bypass open) W.L-1.s-1 0.045 0.053 0.97 1.1 Heat exchanger efficiency Table 1: Indicative performance of commercially available MVHR units Floor area Room Infiltration volume rate m2 m3 56 Classroom Building construction Occupancy (U x A) W.m-2 Air changes per hour Type 1 Type 2 Type 3 Low Mid High 0.1 13 28 48 16 24 32 168 (People) Science lab 80 240 0.1 14 33 62 16 24 32 Assembly hall 300 1,800 0.1 138 176 237 60 100 150 Sports hall 594 4,752 0.1 320 375 455 60 150 250 Large office 375 1,125 0.1 46 138 273 38 50 80 Small office 16 48 0.1 8 28 33 2 4 6 Boardroom 40 120 0.1 17 45 59 10 15 20 Table 2: Basic parameters of modelled rooms occupancy represents a typical physical education lesson and, at high occupancy level, represents it being used as an exam room. There were three commercial building room types a large open-plan office space, a small personal office or meeting room, and a boardroom or large meeting room. Each room variant was modelled with three different occupancy levels representing the occupancy densities given by CIBSE Guide A2 for these room types. Each educational and commercial room type was modelled with three different building constructions to represent buildings with different thermal performances. Room type 1 represented a room with minimal external faades and glazing; type 3 a room with a high level of external faades and glazing; while type 2 represented a middle ground between the two. Fabric thermal performance was taken from limiting values of the 2021 edition of England Building Regulations AD L Volume 2.3 Table 2 provides a summary of the rooms modelled alongside their building constructions (represented by the sum of the U-values multiplied by external area) and occupancy levels. Each room was modelled using internal temperatures, occupancy gains, lighting gains, equipment gains, and ventilation rates as set out in CIBSE Guide A and BB101.4 The ventilation heat recovery required to keep each modelled room variant was heat balanced, or in thermal equilibrium that is, the room heat gains 100% 90% Ventilation heat recovery CPD PROGRAMME Figure 2: Heat recovery efficiency required to maintain thermal equilibrium for a selected set of rooms 80% 70% 60% 50% 40% 30% 20% 10% 0% -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9 10 External temperature ( C) o SEND classroom 1 High-occupancy classroom 2 High-occupancy science lab 3 Low-occupancy assembly hall 3 Sports hall 2 Mid-occupancy large office 2 Mid-occupancy small office 3 High-occupancy small office 1