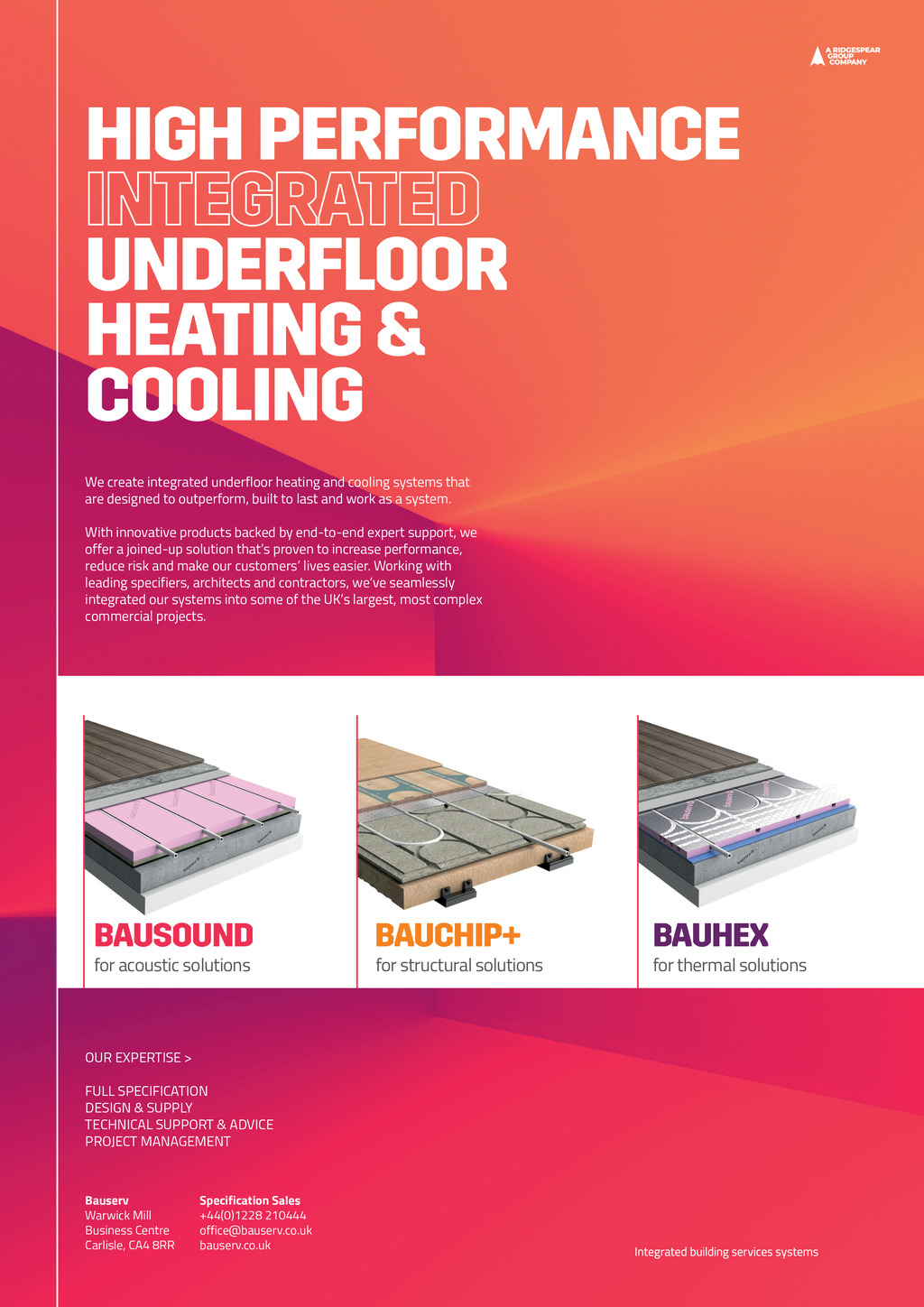

NEWS | WATER HEATERS Heat pump water heater targets gas-replacement market Lochinvars Amicus Aquastore has an output of 8kW and 455 litres of hot-water storage capacity L ochinvar has introduced a new heat pump water heater aimed at the replacement market for gas-fired water heaters in commercial buildings. The Amicus Aquastore is designed to minimise disruption by avoiding the need for wholesale changes to existing heating and hot-water systems. The water heater has an output of 8kW and 455 litres of hot-water storage capacity, in a compact monobloc package combining heat pump and storage vessel. Lochinvar says it can deliver up to 65C hot water in both efficiency and hybrid modes, and can deliver up to 490 litres in a peak hour with a 50C temperature rise. The units are tested according to EN 16147:2017. As such, the coefficient of performance (COP) and seasonal coefficient of performance (SCOP) are the same, at 3.2. Lochinvar says that, because its an internal product, the standard testing only requires the unit to be tested in a room at 20C, so it has not tested COP-SCOP at different plantroom temperatures. It will be testing the unit at different plantroom temperatures, but says it will take time, as it has to book laboratory time. Refrigerant R134A is used with a very low charge of 1.85kg. This has a lower global warming potential than some, more traditional, refrigerants such as R410A but it is A1 class, stable and reliable at higher temperatures. 48 April 2023 www.cibsejournal.com The Amicus Aquastore from Lochinvar Lochinvar says Amicus heat pumps can be used as standalone replacements for conventional heating products, or as part of an integrated system providing pre-heated feed water to gas-fired condensing boilers, water heaters and thermal stores in buildings with large heating or hot-water demands. Installation can be completed by any competent plumber; as the unit is monobloc, with a very small refrigerant charge (1.85kg), installation/commissioning can be completed without any F-gas qualifications. General yearly maintenance on the unit can also be carried out by a competent plumber as, again, there are no F-gas items that need regular maintenance. Should a fault occur on the refrigerant side, a F-gas-certified engineer would be required. As a monobloc heat pump, might there be some trade-off against using a split such as losing some efficiency, more noise or vibration, and ducting requirements? The monobloc unit is designed to be fitted inside without ducts. Noise is not an issue, as the level is probably no higher than lots of other equipment within the plantroom. The unit does need to be ventilated sufficiently if it is in a small area, as the heat pump will cool the plantroom down. Efficiency is kept high by using the refrigerant gas directly to heat a gas coil around the outside of the storage vessel, rather than using a plate heat exchanger. In terms of cost, compared kW for kW with a natural gas system, our closest gas condensing unit, at 11kW, is roughly half the capital cost. However, it would be more expensive to install because of the flue and commissioning, so the gas unit would work out a third cheaper to purchase and install. Lochinvar says it is not able to provide embodied energy estimations for the equipment yet, but is looking at using CIBSE TM65 to calculate the figure.