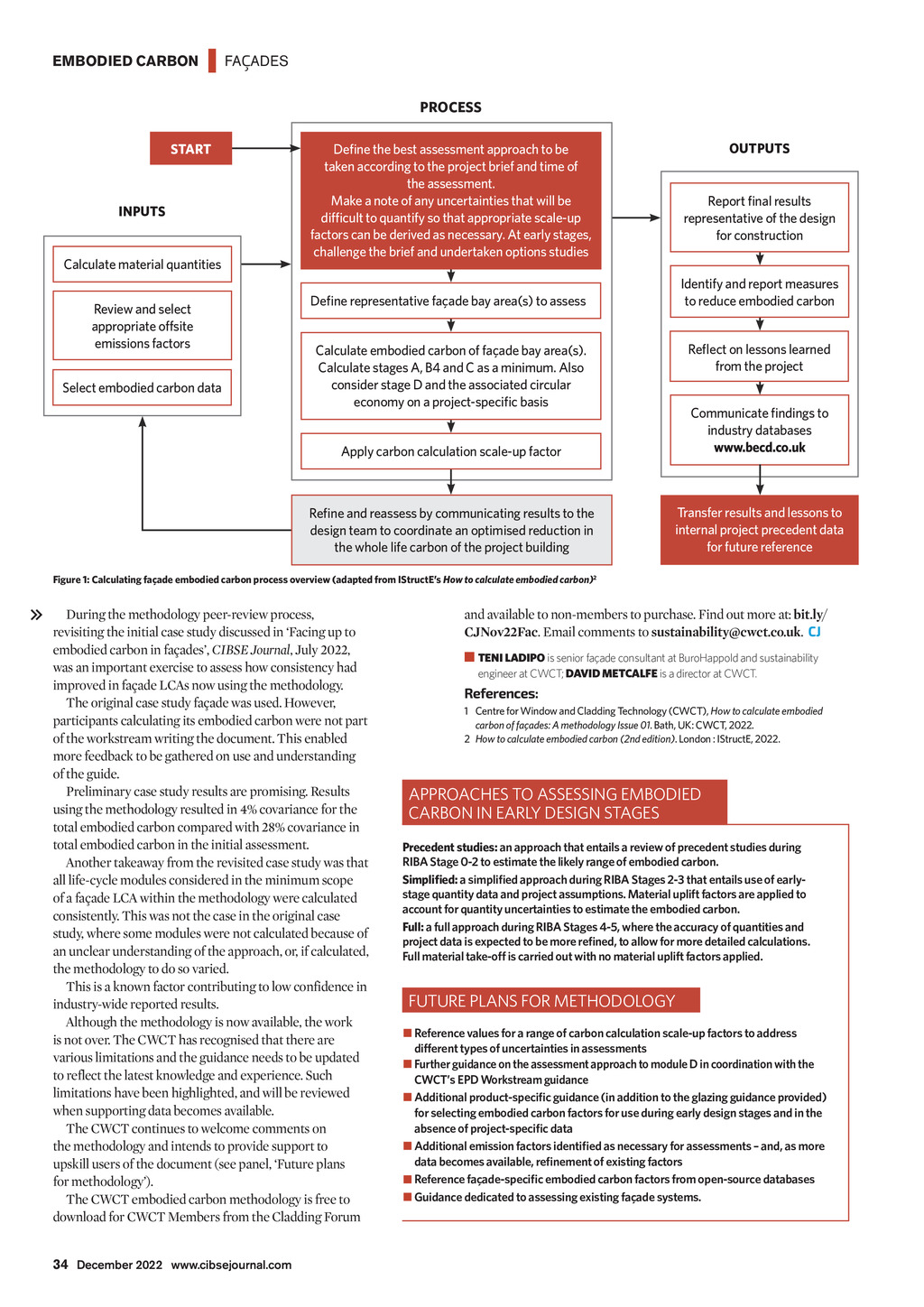

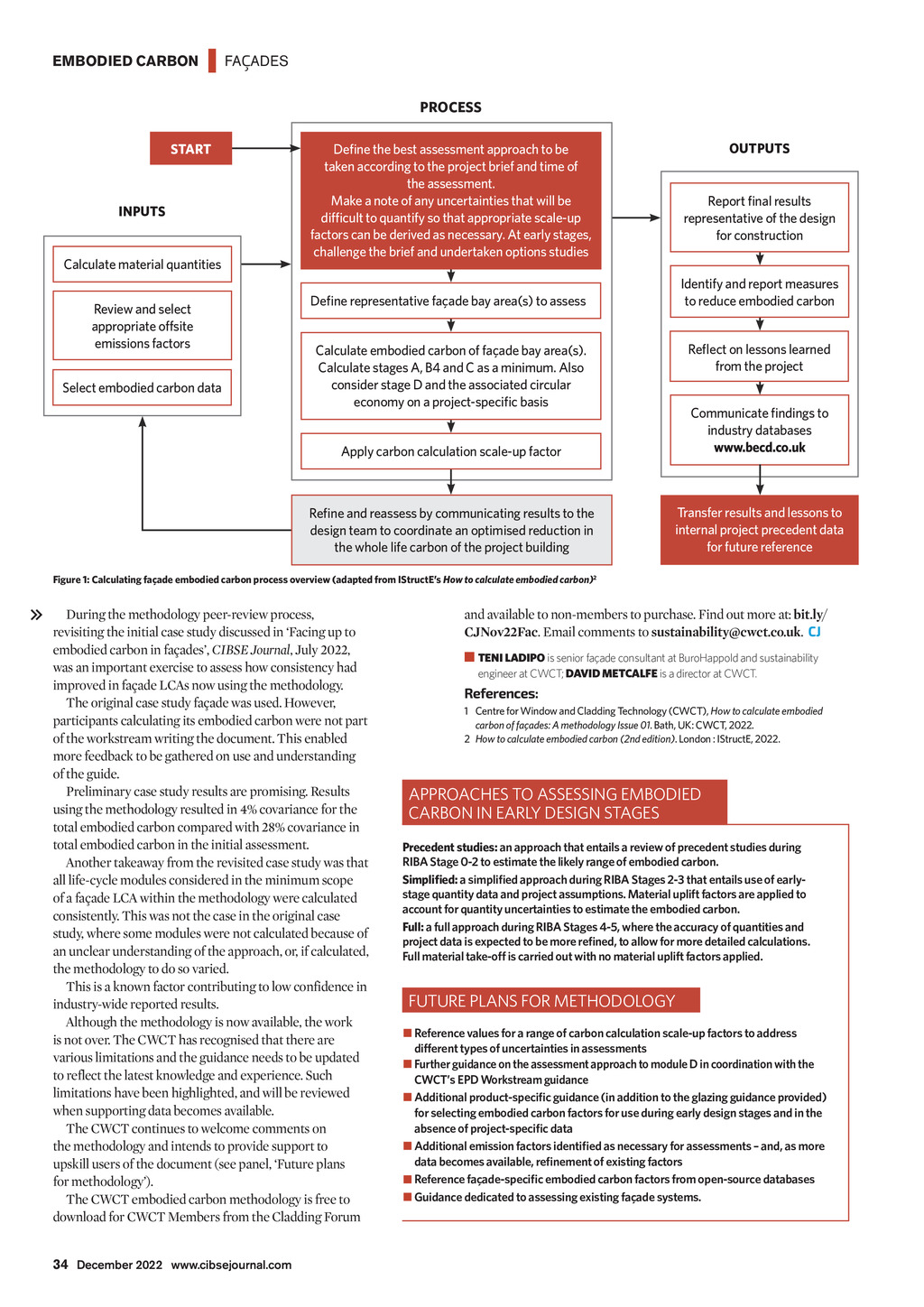

EMBODIED CARBON | FAADES PROCESS START INPUTS Calculate material quantities Review and select appropriate offsite emissions factors Select embodied carbon data OUTPUTS Define the best assessment approach to be taken according to the project brief and time of the assessment. Make a note of any uncertainties that will be difficult to quantify so that appropriate scale-up factors can be derived as necessary. At early stages, challenge the brief and undertaken options studies Report final results representative of the design for construction Identify and report measures to reduce embodied carbon Define representative faade bay area(s) to assess Reflect on lessons learned from the project Calculate embodied carbon of faade bay area(s). Calculate stages A, B4 and C as a minimum. Also consider stage D and the associated circular economy on a project-specific basis Apply carbon calculation scale-up factor Communicate findings to industry databases www.becd.co.uk Refine and reassess by communicating results to the design team to coordinate an optimised reduction in the whole life carbon of the project building Transfer results and lessons to internal project precedent data for future reference Figure 1: Calculating faade embodied carbon process overview (adapted from IStructEs How to calculate embodied carbon)2 During the methodology peer-review process, revisiting the initial case study discussed in Facing up to embodied carbon in faades, CIBSE Journal, July 2022, was an important exercise to assess how consistency had improved in faade LCAs now using the methodology. The original case study faade was used. However, participants calculating its embodied carbon were not part of the workstream writing the document. This enabled more feedback to be gathered on use and understanding of the guide. Preliminary case study results are promising. Results using the methodology resulted in 4% covariance for the total embodied carbon compared with 28% covariance in total embodied carbon in the initial assessment. Another takeaway from the revisited case study was that all life-cycle modules considered in the minimum scope of a faade LCA within the methodology were calculated consistently. This was not the case in the original case study, where some modules were not calculated because of an unclear understanding of the approach, or, if calculated, the methodology to do so varied. This is a known factor contributing to low confidence in industry-wide reported results. Although the methodology is now available, the work is not over. The CWCT has recognised that there are various limitations and the guidance needs to be updated to reflect the latest knowledge and experience. Such limitations have been highlighted, and will be reviewed when supporting data becomes available. The CWCT continues to welcome comments on the methodology and intends to provide support to upskill users of the document (see panel, Future plans for methodology). The CWCT embodied carbon methodology is free to download for CWCT Members from the Cladding Forum and available to non-members to purchase. Find out more at: bit.ly/ CJNov22Fac. Email comments to sustainability@cwct.co.uk. CJ TENI LADIPO is senior faade consultant at BuroHappold and sustainability engineer at CWCT; DAVID METCALFE is a director at CWCT. References: 1 Centre for Window and Cladding Technology (CWCT), How to calculate embodied carbon of faades: A methodology Issue 01. Bath, UK: CWCT, 2022. 2 How to calculate embodied carbon (2nd edition). London : IStructE, 2022. APPROACHES TO ASSESSING EMBODIED CARBON IN EARLY DESIGN STAGES Precedent studies: an approach that entails a review of precedent studies during RIBA Stage 0-2 to estimate the likely range of embodied carbon. Simplified: a simplified approach during RIBA Stages 2-3 that entails use of earlystage quantity data and project assumptions. Material uplift factors are applied to account for quantity uncertainties to estimate the embodied carbon. Full: a full approach during RIBA Stages 4-5, where the accuracy of quantities and project data is expected to be more refined, to allow for more detailed calculations. Full material take-off is carried out with no material uplift factors applied. FUTURE PLANS FOR METHODOLOGY n Reference values for a range of carbon calculation scale-up factors to address different types of uncertainties in assessments n Further guidance on the assessment approach to module D in coordination with the CWCTs EPD Workstream guidance n Additional product-specific guidance (in addition to the glazing guidance provided) for selecting embodied carbon factors for use during early design stages and in the absence of project-specific data n Additional emission factors identified as necessary for assessments and, as more data becomes available, refinement of existing factors n Reference faade-specific embodied carbon factors from open-source databases n Guidance dedicated to assessing existing faade systems. 34 December 2022 www.cibsejournal.com CIBSE Dec 22 pp33-34 Facade embodied carbon.indd 34 25/11/2022 18:08