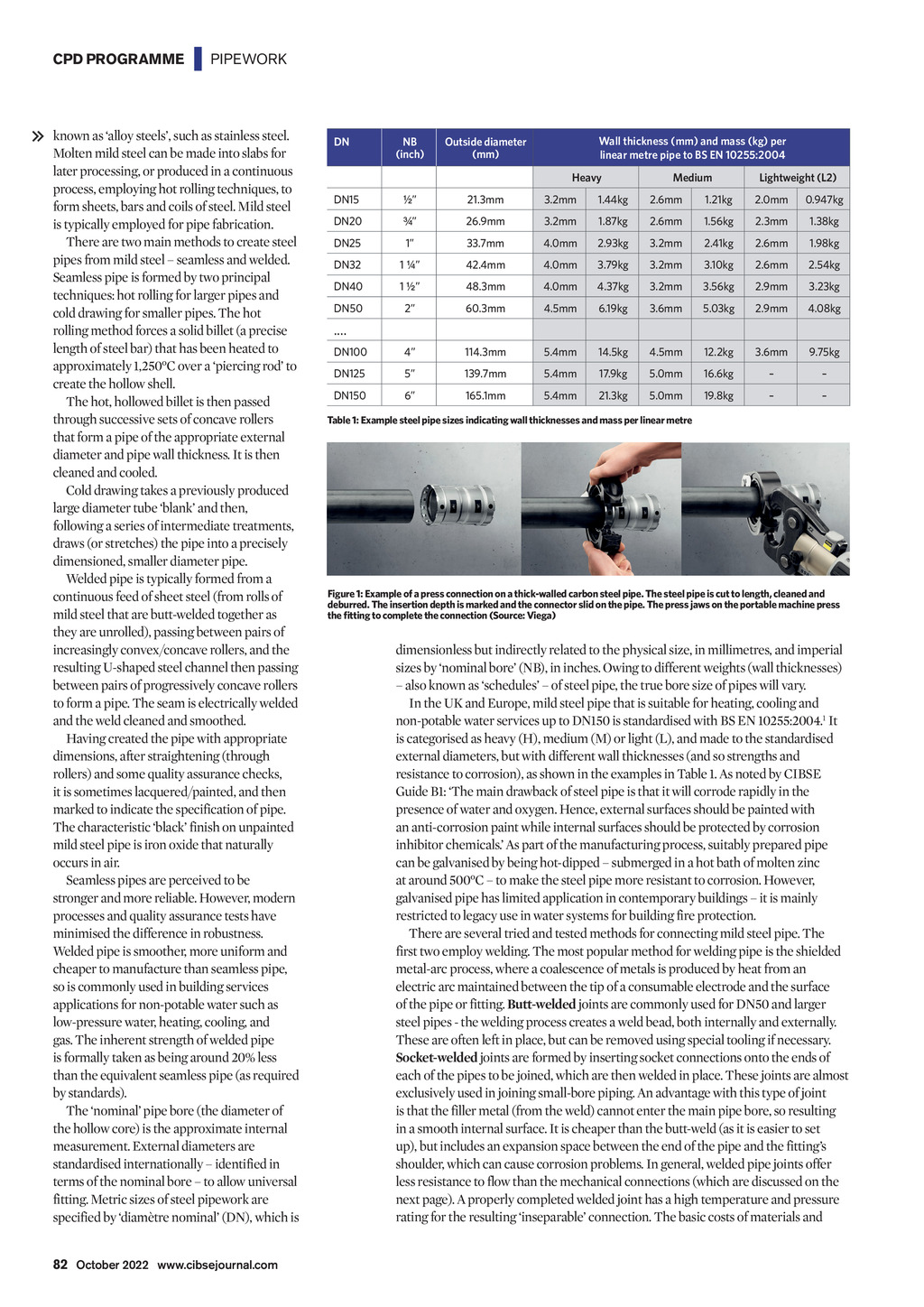

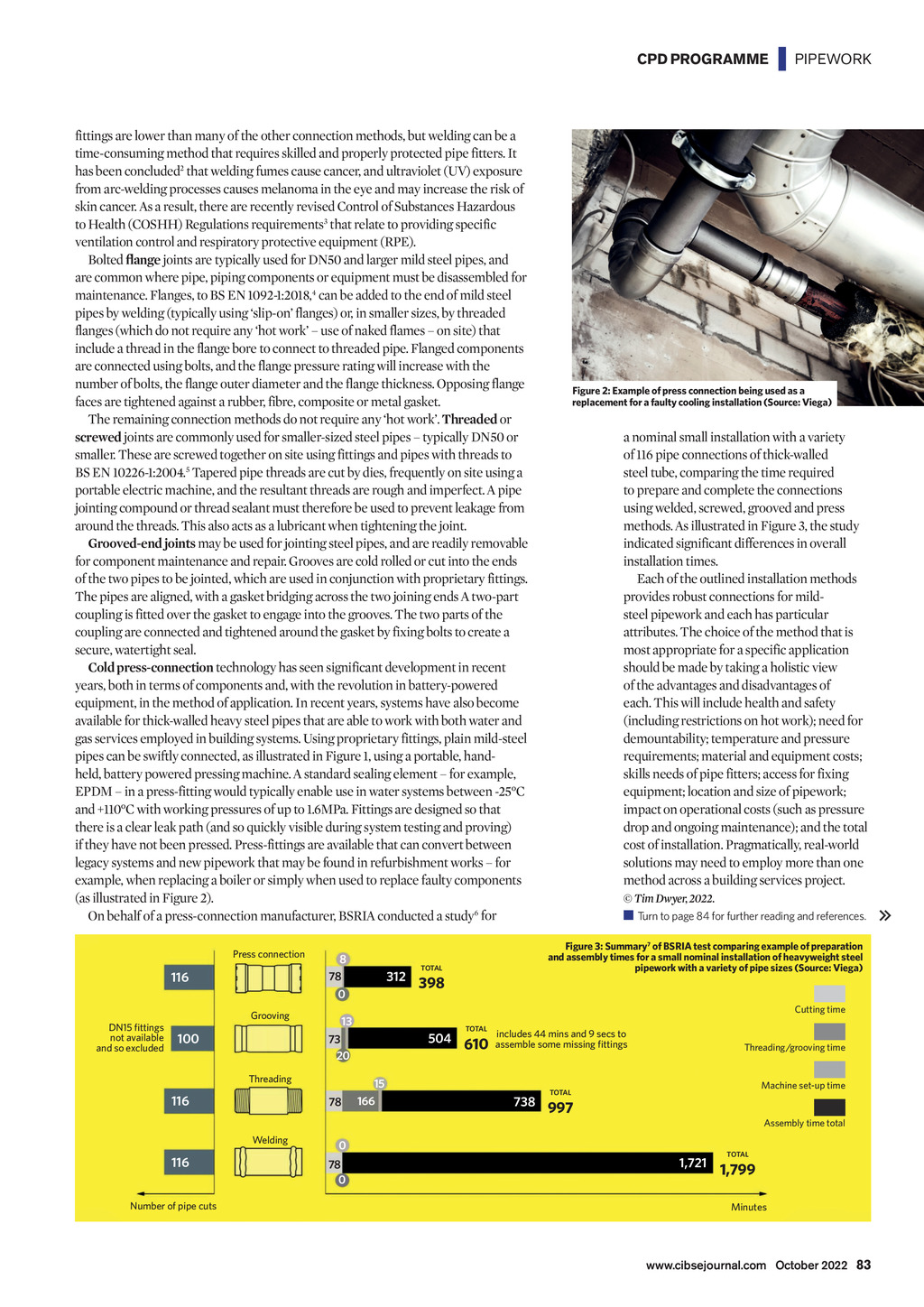

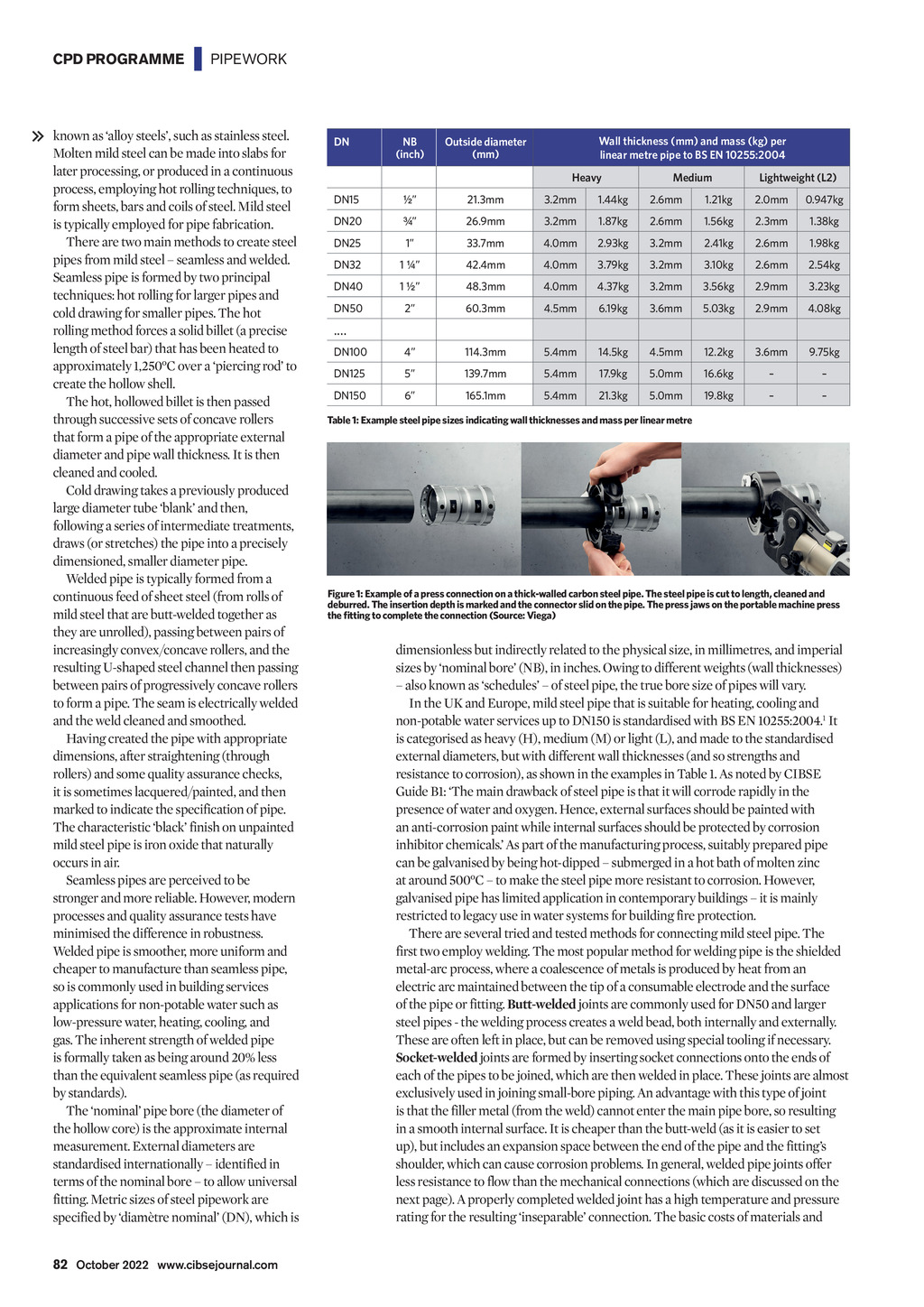

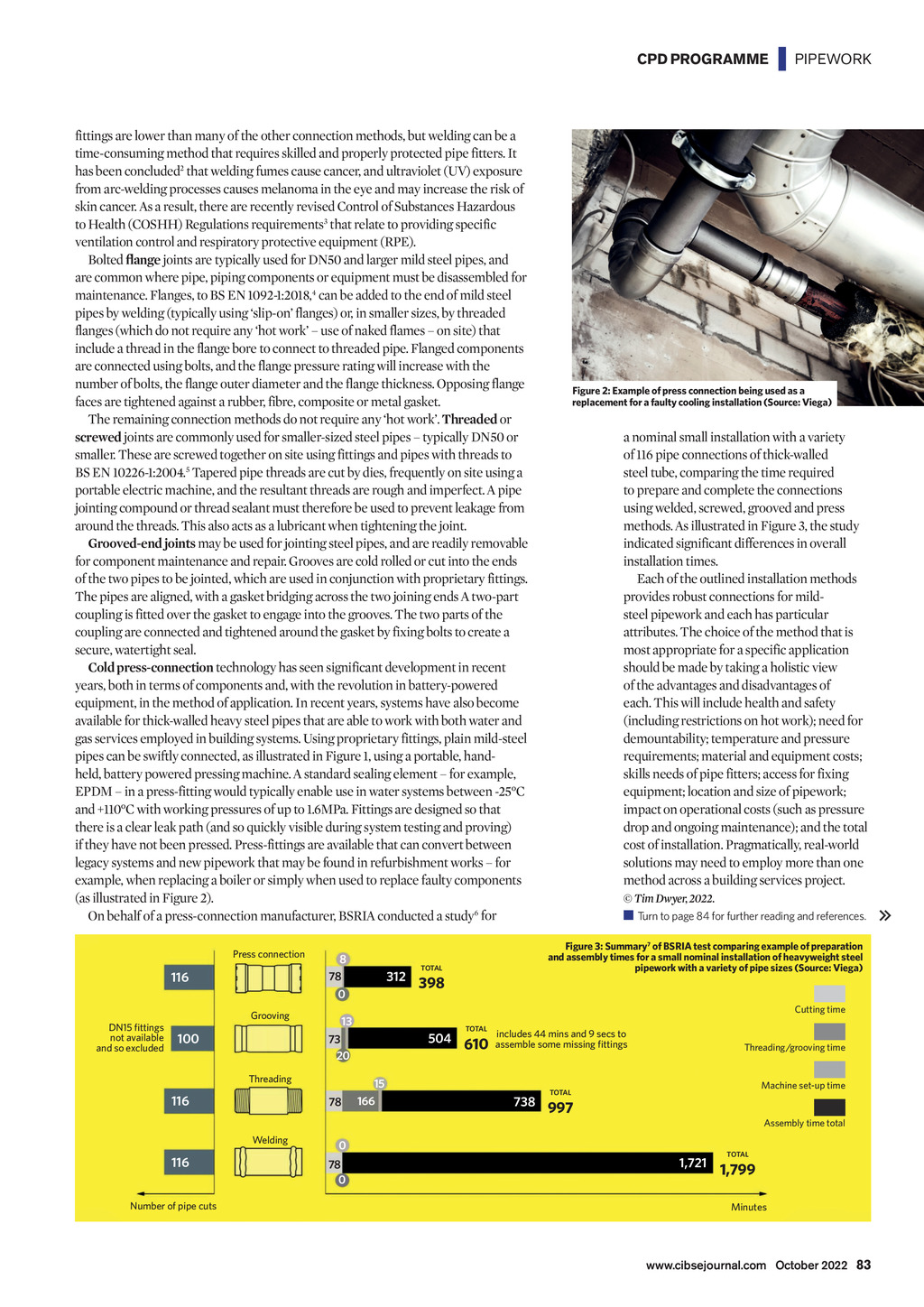

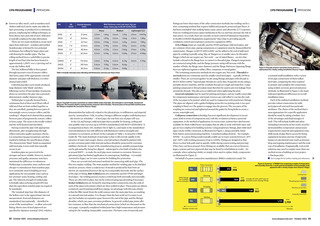

CPD PROGRAMME | PIPEWORK known as alloy steels, such as stainless steel. Molten mild steel can be made into slabs for later processing, or produced in a continuous process, employing hot rolling techniques, to form sheets, bars and coils of steel. Mild steel is typically employed for pipe fabrication. There are two main methods to create steel pipes from mild steel seamless and welded. Seamless pipe is formed by two principal techniques: hot rolling for larger pipes and cold drawing for smaller pipes. The hot rolling method forces a solid billet (a precise length of steel bar) that has been heated to approximately 1,250C over a piercing rod to create the hollow shell. The hot, hollowed billet is then passed through successive sets of concave rollers that form a pipe of the appropriate external diameter and pipe wall thickness. It is then cleaned and cooled. Cold drawing takes a previously produced large diameter tube blank and then, following a series of intermediate treatments, draws (or stretches) the pipe into a precisely dimensioned, smaller diameter pipe. Welded pipe is typically formed from a continuous feed of sheet steel (from rolls of mild steel that are butt-welded together as they are unrolled), passing between pairs of increasingly convex/concave rollers, and the resulting U-shaped steel channel then passing between pairs of progressively concave rollers to form a pipe. The seam is electrically welded and the weld cleaned and smoothed. Having created the pipe with appropriate dimensions, after straightening (through rollers) and some quality assurance checks, it is sometimes lacquered/painted, and then marked to indicate the specification of pipe. The characteristic black finish on unpainted mild steel pipe is iron oxide that naturally occurs in air. Seamless pipes are perceived to be stronger and more reliable. However, modern processes and quality assurance tests have minimised the difference in robustness. Welded pipe is smoother, more uniform and cheaper to manufacture than seamless pipe, so is commonly used in building services applications for non-potable water such as low-pressure water, heating, cooling, and gas. The inherent strength of welded pipe is formally taken as being around 20% less than the equivalent seamless pipe (as required by standards). The nominal pipe bore (the diameter of the hollow core) is the approximate internal measurement. External diameters are standardised internationally identified in terms of the nominal bore to allow universal fitting. Metric sizes of steel pipework are specified by diamtre nominal (DN), which is NB (inch) Outside diameter (mm) DN15 21.3mm DN20 26.9mm DN25 1 33.7mm DN32 1 42.4mm DN40 1 48.3mm DN50 2 DN Wall thickness (mm) and mass (kg) per linear metre pipe to BS EN 10255:2004 Heavy 3.2mm Medium Lightweight (L2) 1.44kg 2.6mm 1.21kg 2.0mm 0.947kg 3.2mm 1.87kg 2.6mm 1.56kg 2.3mm 1.38kg 4.0mm 2.93kg 3.2mm 2.41kg 2.6mm 1.98kg 4.0mm 3.79kg 3.2mm 3.10kg 2.6mm 2.54kg 4.0mm 4.37kg 3.2mm 3.56kg 2.9mm 3.23kg 60.3mm 4.5mm 6.19kg 3.6mm 5.03kg 2.9mm 4.08kg .... DN100 4 114.3mm 5.4mm 14.5kg 4.5mm 12.2kg 3.6mm 9.75kg DN125 5 139.7mm 5.4mm 17.9kg 5.0mm 16.6kg DN150 6 165.1mm 5.4mm 21.3kg 5.0mm 19.8kg Table 1: Example steel pipe sizes indicating wall thicknesses and mass per linear metre Figure 1: Example of a press connection on a thick-walled carbon steel pipe. The steel pipe is cut to length, cleaned and deburred. The insertion depth is marked and the connector slid on the pipe. The press jaws on the portable machine press the fitting to complete the connection (Source: Viega) dimensionless but indirectly related to the physical size, in millimetres, and imperial sizes by nominal bore (NB), in inches. Owing to different weights (wall thicknesses) also known as schedules of steel pipe, the true bore size of pipes will vary. In the UK and Europe, mild steel pipe that is suitable for heating, cooling and non-potable water services up to DN150 is standardised with BS EN 10255:2004.1 It is categorised as heavy (H), medium (M) or light (L), and made to the standardised external diameters, but with different wall thicknesses (and so strengths and resistance to corrosion), as shown in the examples in Table 1. As noted by CIBSE Guide B1: The main drawback of steel pipe is that it will corrode rapidly in the presence of water and oxygen. Hence, external surfaces should be painted with an anti-corrosion paint while internal surfaces should be protected by corrosion inhibitor chemicals. As part of the manufacturing process, suitably prepared pipe can be galvanised by being hot-dipped submerged in a hot bath of molten zinc at around 500C to make the steel pipe more resistant to corrosion. However, galvanised pipe has limited application in contemporary buildings it is mainly restricted to legacy use in water systems for building fire protection. There are several tried and tested methods for connecting mild steel pipe. The first two employ welding. The most popular method for welding pipe is the shielded metal-arc process, where a coalescence of metals is produced by heat from an electric arc maintained between the tip of a consumable electrode and the surface of the pipe or fitting. Butt-welded joints are commonly used for DN50 and larger steel pipes - the welding process creates a weld bead, both internally and externally. These are often left in place, but can be removed using special tooling if necessary. Socket-welded joints are formed by inserting socket connections onto the ends of each of the pipes to be joined, which are then welded in place. These joints are almost exclusively used in joining small-bore piping. An advantage with this type of joint is that the filler metal (from the weld) cannot enter the main pipe bore, so resulting in a smooth internal surface. It is cheaper than the butt-weld (as it is easier to set up), but includes an expansion space between the end of the pipe and the fittings shoulder, which can cause corrosion problems. In general, welded pipe joints offer less resistance to flow than the mechanical connections (which are discussed on the next page). A properly completed welded joint has a high temperature and pressure rating for the resulting inseparable connection. The basic costs of materials and 82 October 2022 www.cibsejournal.com CIBSE Oct 22 pp81-84 CPD 203.indd 82 26/09/2022 15:27