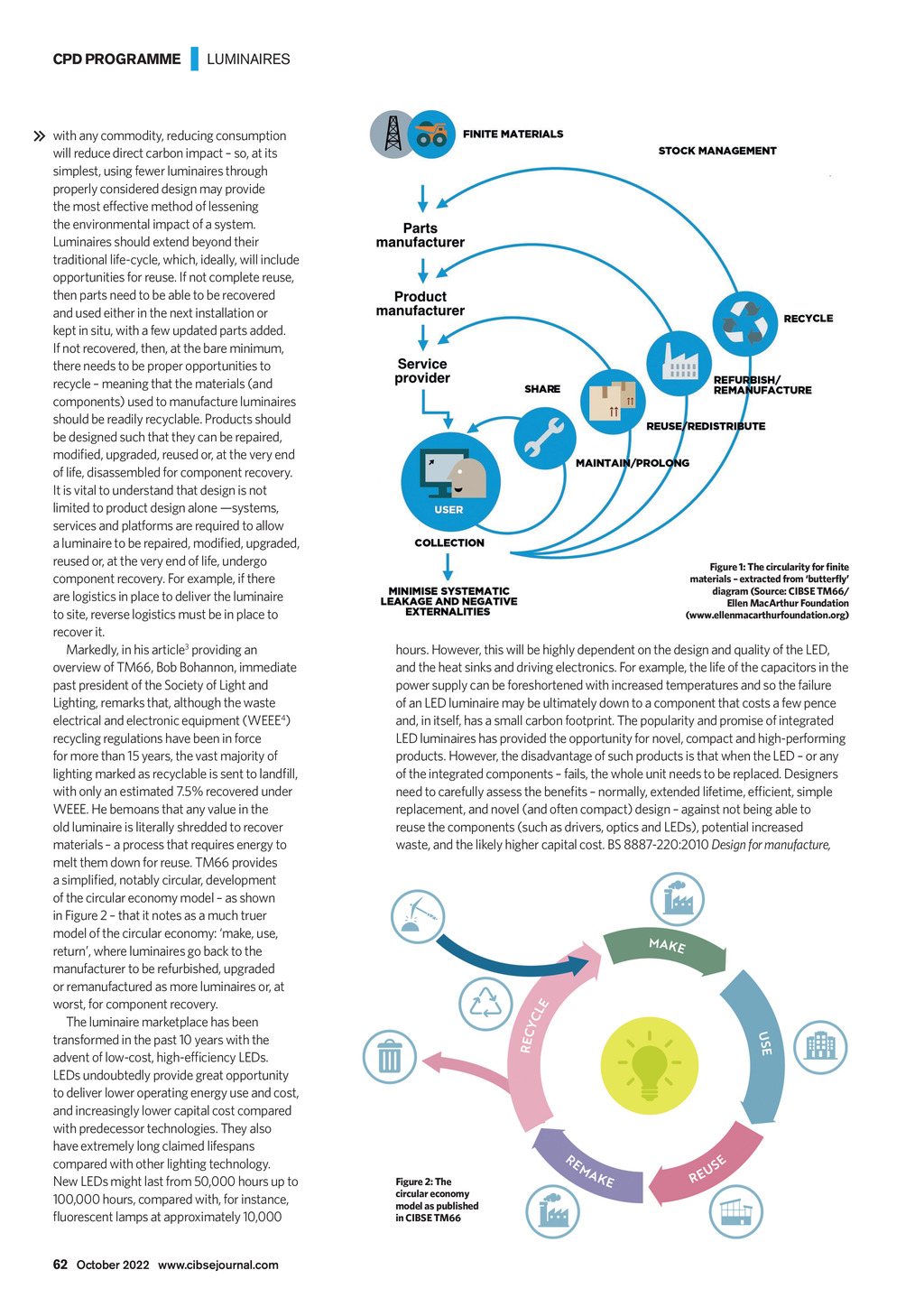

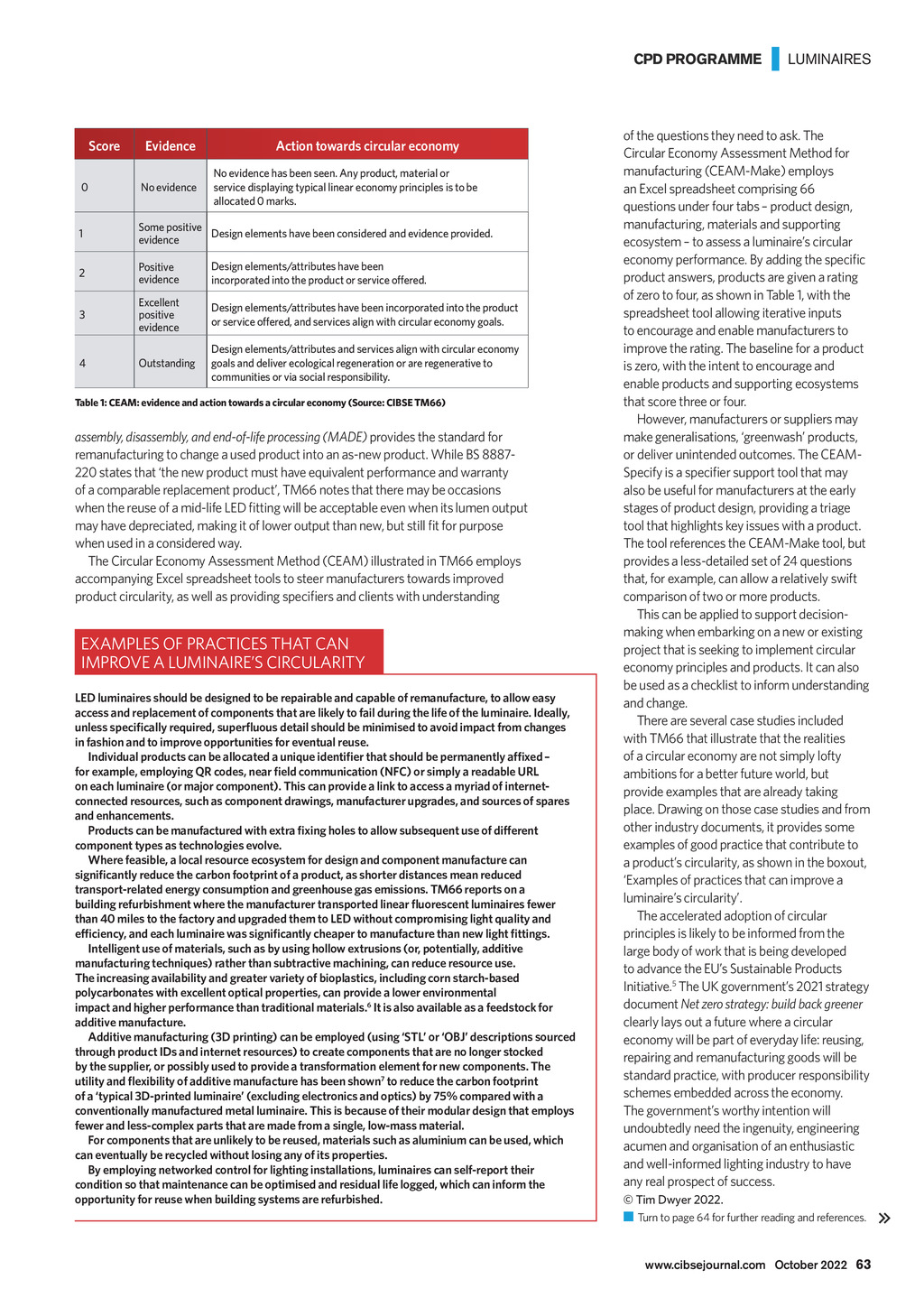

CPD PROGRAMME | LUMINAIRES with any commodity, reducing consumption will reduce direct carbon impact so, at its simplest, using fewer luminaires through properly considered design may provide the most effective method of lessening the environmental impact of a system. Luminaires should extend beyond their traditional life-cycle, which, ideally, will include opportunities for reuse. If not complete reuse, then parts need to be able to be recovered and used either in the next installation or kept in situ, with a few updated parts added. If not recovered, then, at the bare minimum, there needs to be proper opportunities to recycle meaning that the materials (and components) used to manufacture luminaires should be readily recyclable. Products should be designed such that they can be repaired, modified, upgraded, reused or, at the very end of life, disassembled for component recovery. It is vital to understand that design is not limited to product design alone systems, services and platforms are required to allow a luminaire to be repaired, modified, upgraded, reused or, at the very end of life, undergo component recovery. For example, if there are logistics in place to deliver the luminaire to site, reverse logistics must be in place to recover it. Markedly, in his article3 providing an overview of TM66, Bob Bohannon, immediate past president of the Society of Light and Lighting, remarks that, although the waste electrical and electronic equipment (WEEE4) recycling regulations have been in force for more than 15 years, the vast majority of lighting marked as recyclable is sent to landfill, with only an estimated 7.5% recovered under WEEE. He bemoans that any value in the old luminaire is literally shredded to recover materials a process that requires energy to melt them down for reuse. TM66 provides a simplified, notably circular, development of the circular economy model as shown in Figure 2 that it notes as a much truer model of the circular economy: make, use, return, where luminaires go back to the manufacturer to be refurbished, upgraded or remanufactured as more luminaires or, at worst, for component recovery. The luminaire marketplace has been transformed in the past 10 years with the advent of low-cost, high-efficiency LEDs. LEDs undoubtedly provide great opportunity to deliver lower operating energy use and cost, and increasingly lower capital cost compared with predecessor technologies. They also have extremely long claimed lifespans compared with other lighting technology. New LEDs might last from 50,000 hours up to 100,000 hours, compared with, for instance, fluorescent lamps at approximately 10,000 Figure 1: The circularity for finite materials extracted from butterfly diagram (Source: CIBSE TM66/ Ellen MacArthur Foundation (www.ellenmacarthurfoundation.org) hours. However, this will be highly dependent on the design and quality of the LED, and the heat sinks and driving electronics. For example, the life of the capacitors in the power supply can be foreshortened with increased temperatures and so the failure of an LED luminaire may be ultimately down to a component that costs a few pence and, in itself, has a small carbon footprint. The popularity and promise of integrated LED luminaires has provided the opportunity for novel, compact and high-performing products. However, the disadvantage of such products is that when the LED or any of the integrated components fails, the whole unit needs to be replaced. Designers need to carefully assess the benefits normally, extended lifetime, efficient, simple replacement, and novel (and often compact) design against not being able to reuse the components (such as drivers, optics and LEDs), potential increased waste, and the likely higher capital cost. BS 8887-220:2010 Design for manufacture, Figure 2: The circular economy model as published in CIBSE TM66 62 October 2022 www.cibsejournal.com CIBSE Oct 22 pp61-64 CPD 204 Supp.indd 62 26/09/2022 15:50