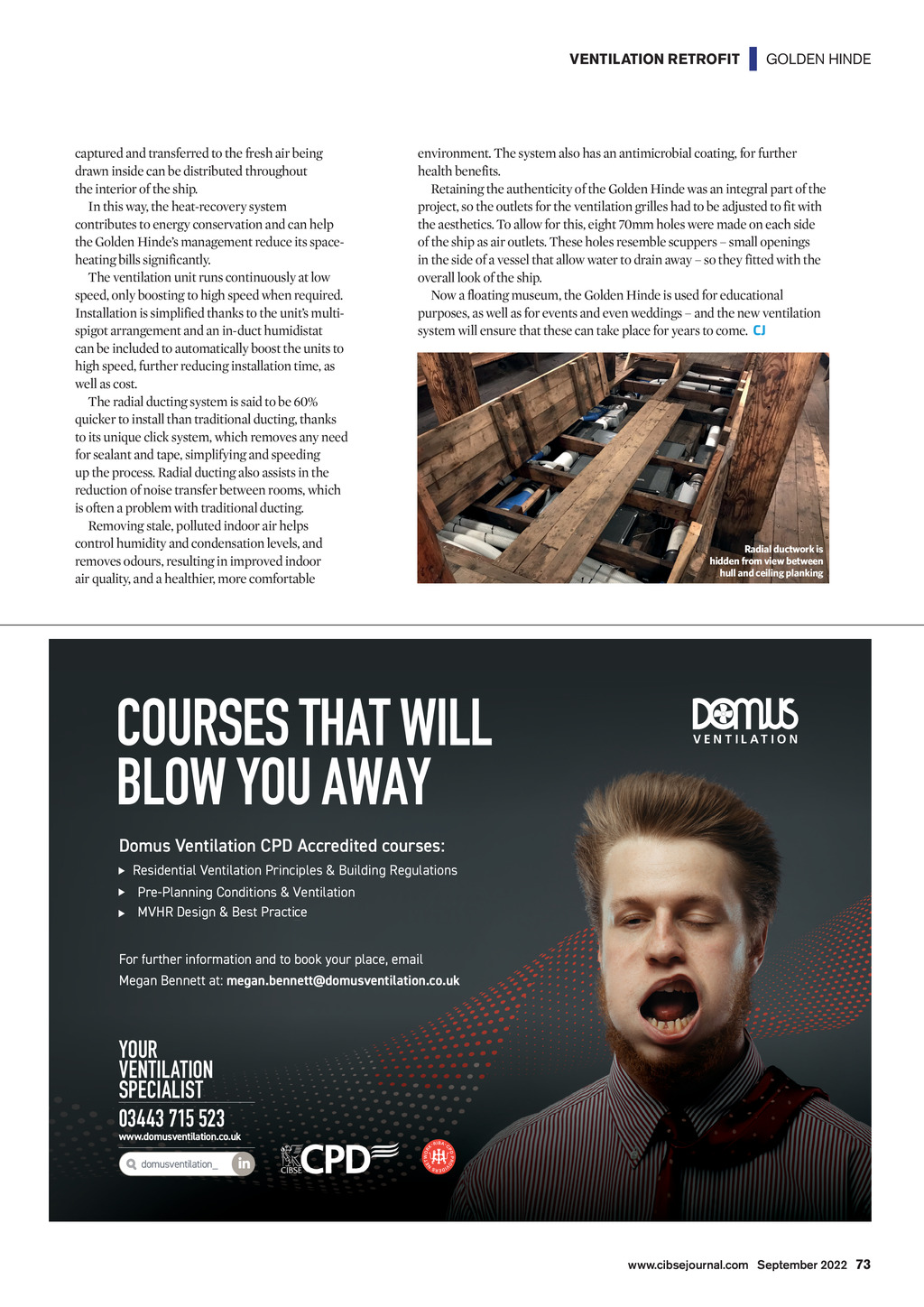

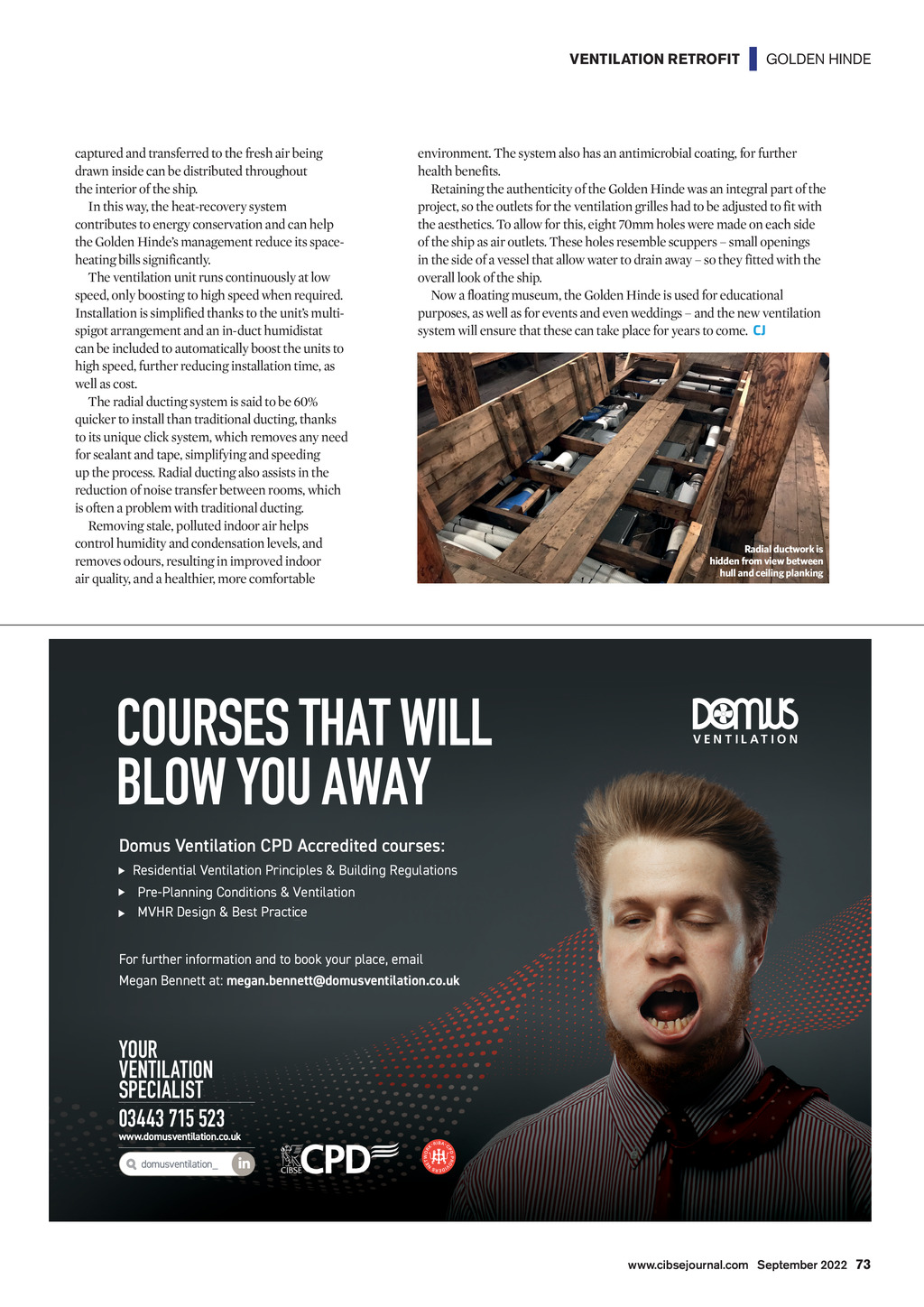

VENTILATION RETROFIT | GOLDEN HINDE Finding space in the ship to install kit that would achieve the necessary number of air changes per hour was a challenge good level of ventilation. Millinder has detailed knowledge of the build and functions of the ship, so his collaboration was crucial to ensure the design was appropriate for the ships structure. Two site visits were conducted to make sure the ventilation system would function once it was in situ. Finding space in the ship to install kit that would achieve the number of air changes per hour necessary for a safe environment for the public was a challenge. With careful consideration, however, the final design exceeded expected changes by 25%. Heat recovery SHIP SHAPE To preserve the timbers of the Golden Hinde, a ventilation system with heat recovery had to be designed that could be squeezed into the compact, curved spaces of the replica 16th-century ship. Molly Tooher-Rudd finds out how they did it T he Golden Hinde is a full-size reconstruction of the English galleon captained by Sir Francis Drake on his circumnavigation of the globe in the 16th century. Launched in 1973, the ship sailed more than 140,000 miles before being retired and docked at Londons South Bank in 2003. Suffering from rotting timbers, the Golden Hinde is undergoing a major refit, using traditional materials and classical methods. . Poor levels of ventilation can lead to increased levels of condensation, which, over time, can cause significant damage. If not managed, the rot caused by these conditions can impact the strength of the structural timber, which poses a danger for visitors to the ship. The design processes The Golden Hindes lead shipwright, Toby Millinder, worked with National Ventilation to create an effective, practical system that would achieve a During the design process, National Ventilation specified heat-recovery ventilation to recover waste heat. Using the project drawings, specialist knowledge of the equipment from engineers at National Ventilation, and software programs, a correctly sized ventilation unit and the correct type and lengths of ducting were specified. Because of the space restrictions, it was necessary to specify two Monsoon HRU/ ECO150EC mechanical ventilation with heat recovery (MVHR) units and two inline heaters one for each MVHR unit which will provide comfort heating for visitors. National Ventilation commissioned and balanced the system. The project presented a number of challenges for the ventilation team. Ductwork is generally run in straight lines, but the hull of a ship is curved, so a compact solution was needed that could accommodate the bends of the ship. Radial ducting was specified, which, in its simplest form, consists of a central plenum that feeds a network of radially arranged branch ducts. This was the perfect solution, as the flexibility of this type of ducting allowed for unforeseen circumstances during installation, while its smaller diameter means it is crush-resistant and sturdier than alternatives. National Ventilations Monsoon 75mm radial ducting was used, and could be pulled through the small spaces of the ship without tearing. It is all hidden from view, because it runs between the ceiling planking (on the inside of the hull) and the hull planking. The MVHR units provide good air comfort levels while minimising heat wastage, as heat 72 September 2022 www.cibsejournal.com CIBSE Sept 22 pp72-73 Golden Hinde V2.indd 72 26/08/2022 18:54