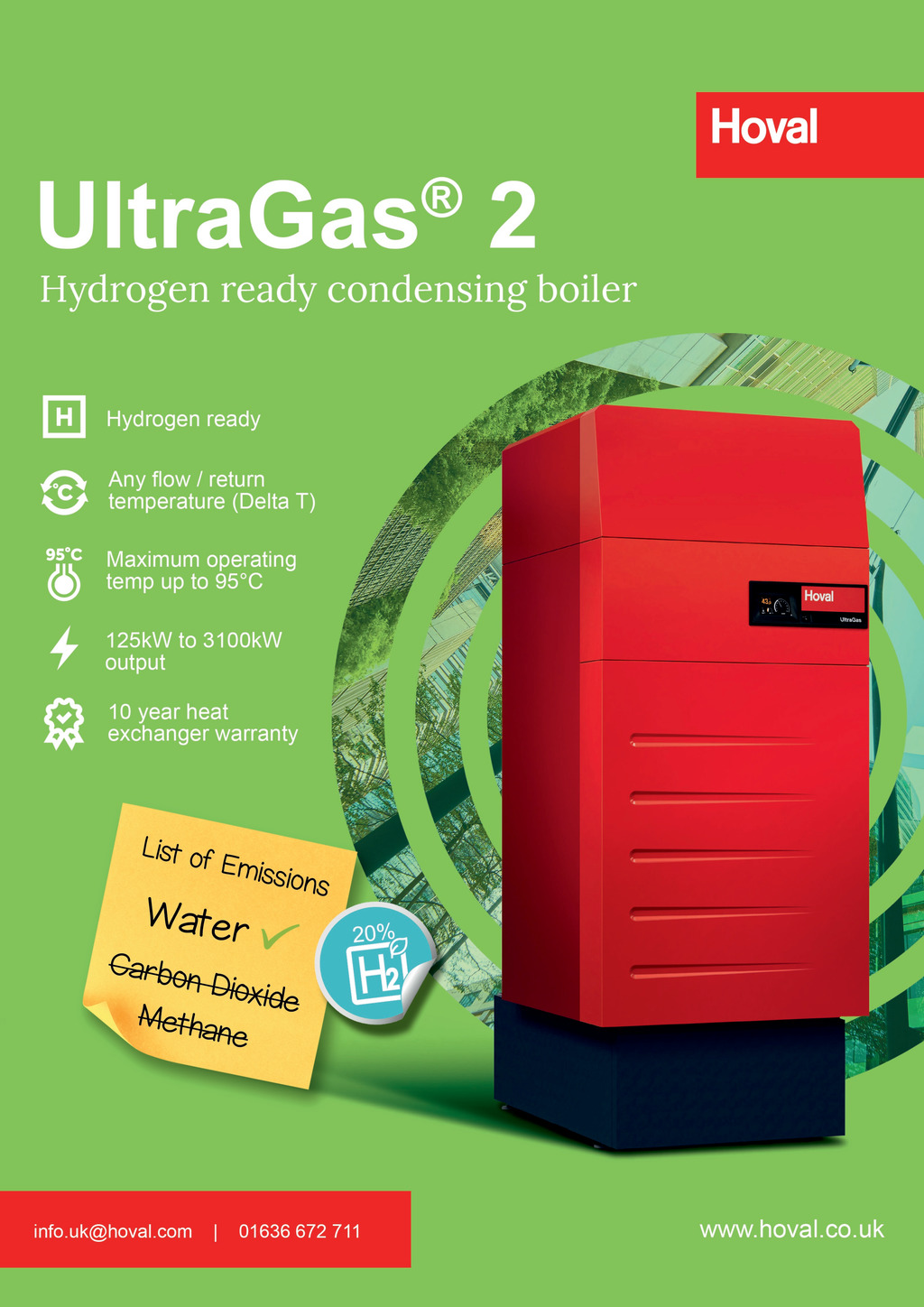

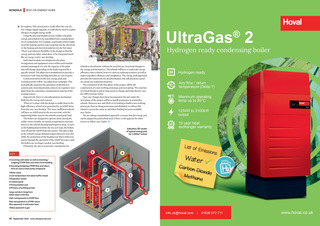

SCHOOLS | BOLT-ON ENERGY HUBS he explains. This stored power could offset the cost of a low-voltage supply upgrade. It could also be used to exploit cheaper overnight energy tariffs. Using the pod and module system enables a bespoke energy pod solution to be assembled from a standardised set of components. For example, a particular school might need the heating and hot water pods but not the electrical; or the heating and electrical pods but not the hot water. There is an inherent flexibility in the design so that the energy pod can either stand alone or be integrated much like an energy centre, says Keeling. Individual modules are designed so the plant arrangement and equipment zones within each module remain unchanged; it is only the capacity of the plant that will change depending on the loads required for a specific school. The plant too is modularised to provide a contractor with what Keeling describes as a kit of parts. Connection between the new energy pods and existing systems will be via a plate heat exchanger. This hydraulically separates the operation of old and new systems and, most importantly, protects an expensive new plant from the sometimes contaminated contents of the existing system. Impressively, there is a decarbonisation mechanism built into the energy pod concept. What weve done with the design is enable heat in the high-efficiency school to be generated by an ASHP alone from day one, says Keeling. The more inefficient schools will have an ASHP sized to the net zero load, with the supporting boiler sized to the schools actual peak load. The boilers are designed to operate alone during the colder winter months. As outside temperatures increase, however, the schools heating load begins to drop. As soon as the building load is below the net zero load, the boilers turn off and the ASHP kicks into action. The idea is that as the schools energy demand reduces between now and 2050, the proportion of the heating year that is delivered purely through the operation of the ASHP increases until the boilers are no longer needed, says Keeling. Ultimately, the aim is to provide a mechanism for schools to decarbonise without the need for any structural changes to the energy pod themselves. The schools will have to undertake energy efficiency interventions, however, such as replacing windows, as well as improving fabric efficiency and airtightness. The energy pods approach provides the framework for decarbonisation, but still promotes action on energy use reduction measures. The conclusion of the first phase of the project will be the construction of a non-working prototype pod next spring. We want lots of critical friends to tell us what needs to change and what doesnt, says the DfEs Gemma Taylor. Once any changes have been incorporated, the aim under the next phase of the project will be to install prototypes in around five schools. Between now and 2025, were looking to build a non-working prototype, then working prototypes and ultimately to roll out this initiative across the estate as and when funding becomes available, says Taylor. We are taking a standardised approach to ensure that the energy pod can be adapted beyond school stock if there is the appetite for other sectors to follow, says Taylor. CJ Indicative 3D render of typical energy pod for 1,250m2 school 5 KEY 4 A Incoming cold water as well as incoming/ outgoing LTHW ow and return from building B Incoming/outgoing LTHW ow and return from air source heat pump compound 1 Boiler stack 2 Low temperature hot water buffer vessel 3 Expansion vessel 4 Control panel 5 Pressurisation unit 6 Primary circulating pumps Large red duct rising from boiler stack is the ue 3 2 6 1 B Dark red pipework is LTHW ow Pale red pipework is LTHW return Blue pipework is cold water feed A Yellow pipework is gas 32 September 2022 www.cibsejournal.com CIBSE Sept 22 pp28-30, 32 Energy pods.indd 32 26/08/2022 18:30