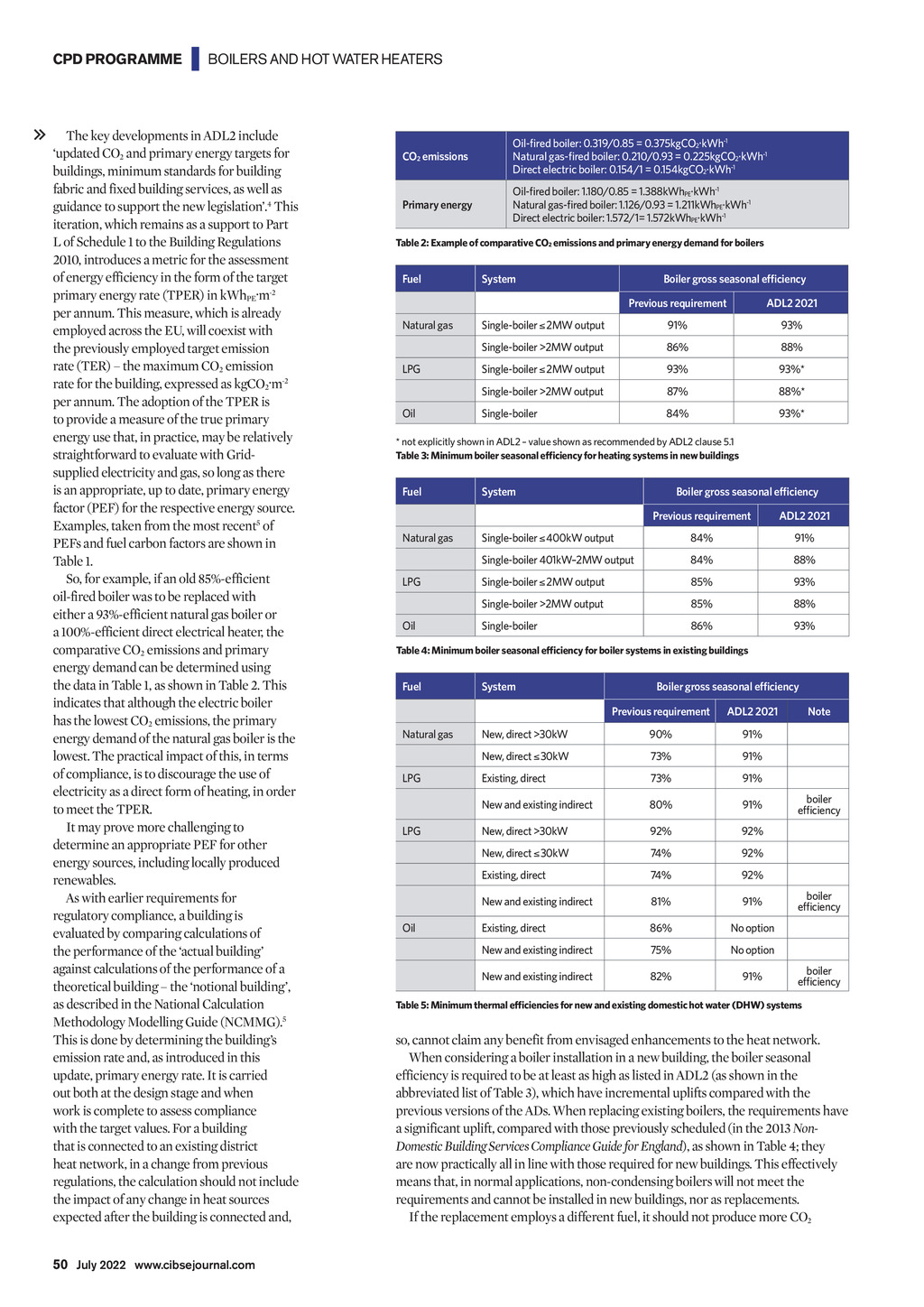

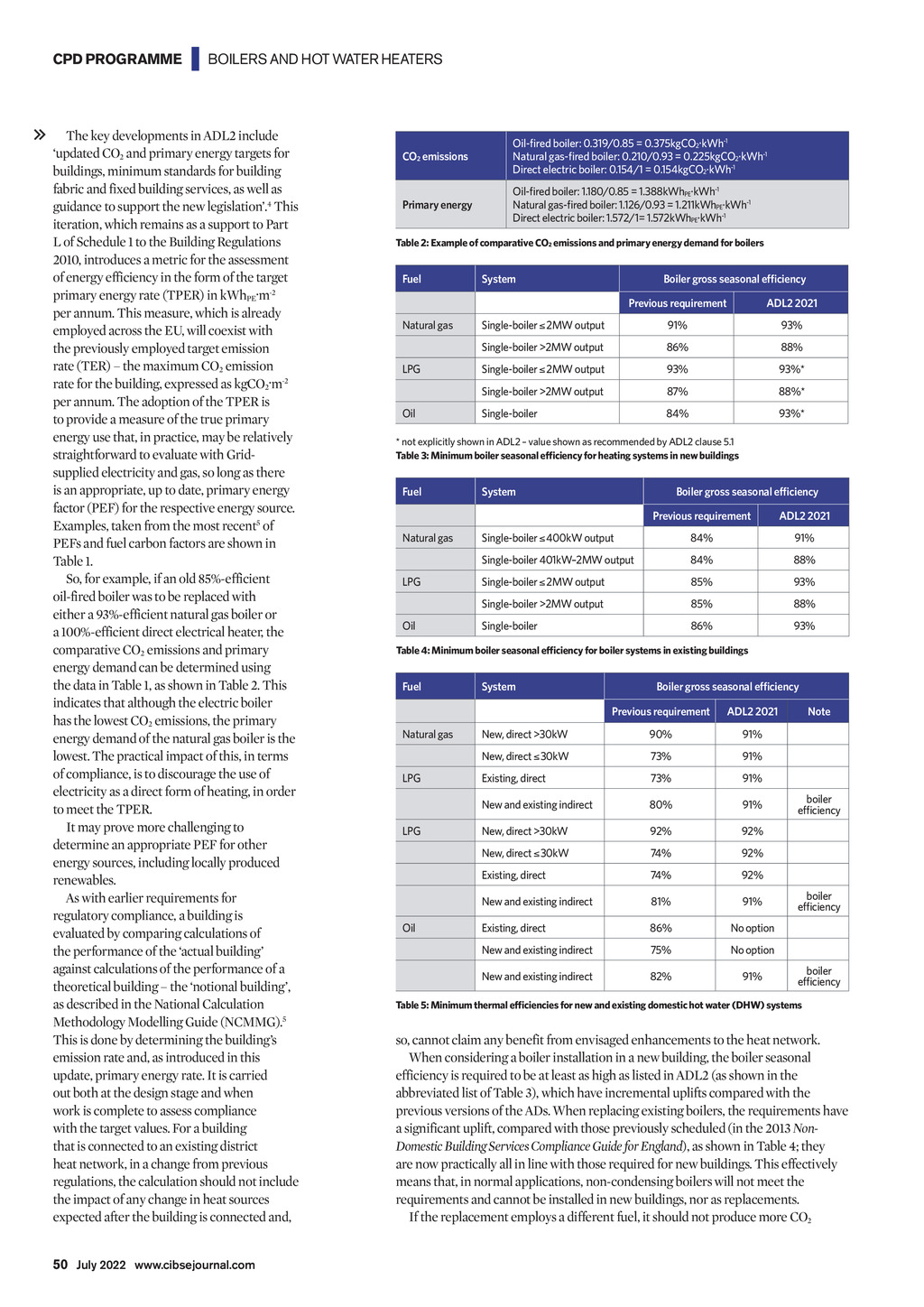

CPD PROGRAMME | BOILERS AND HOT WATER HEATERS The key developments in ADL2 include updated CO2 and primary energy targets for buildings, minimum standards for building fabric and fixed building services, as well as guidance to support the new legislation.4 This iteration, which remains as a support to Part L of Schedule 1 to the Building Regulations 2010, introduces a metric for the assessment of energy efficiency in the form of the target primary energy rate (TPER) in kWhPE.m-2 per annum. This measure, which is already employed across the EU, will coexist with the previously employed target emission rate (TER) the maximum CO2 emission rate for the building, expressed as kgCO2.m-2 per annum. The adoption of the TPER is to provide a measure of the true primary energy use that, in practice, may be relatively straightforward to evaluate with Gridsupplied electricity and gas, so long as there is an appropriate, up to date, primary energy factor (PEF) for the respective energy source. Examples, taken from the most recent5 of PEFs and fuel carbon factors are shown in Table 1. So, for example, if an old 85%-efficient oil-fired boiler was to be replaced with either a 93%-efficient natural gas boiler or a 100%-efficient direct electrical heater, the comparative CO2 emissions and primary energy demand can be determined using the data in Table 1, as shown in Table 2. This indicates that although the electric boiler has the lowest CO2 emissions, the primary energy demand of the natural gas boiler is the lowest. The practical impact of this, in terms of compliance, is to discourage the use of electricity as a direct form of heating, in order to meet the TPER. It may prove more challenging to determine an appropriate PEF for other energy sources, including locally produced renewables. As with earlier requirements for regulatory compliance, a building is evaluated by comparing calculations of the performance of the actual building against calculations of the performance of a theoretical building the notional building, as described in the National Calculation Methodology Modelling Guide (NCMMG).5 This is done by determining the buildings emission rate and, as introduced in this update, primary energy rate. It is carried out both at the design stage and when work is complete to assess compliance with the target values. For a building that is connected to an existing district heat network, in a change from previous regulations, the calculation should not include the impact of any change in heat sources expected after the building is connected and, CO2 emissions Oil-fired boiler: 0.319/0.85 = 0.375kgCO2.kWh-1 Natural gas-fired boiler: 0.210/0.93 = 0.225kgCO2.kWh-1 Direct electric boiler: 0.154/1 = 0.154kgCO2.kWh-1 Primary energy Oil-fired boiler: 1.180/0.85 = 1.388kWhPE.kWh-1 Natural gas-fired boiler: 1.126/0.93 = 1.211kWhPE.kWh-1 Direct electric boiler: 1.572/1= 1.572kWhPE.kWh-1 Table 2: Example of comparative CO2 emissions and primary energy demand for boilers Fuel System Previous requirement ADL2 2021 Natural gas Single-boiler 2MW output 91% 93% Single-boiler >2MW output 86% 88% LPG Single-boiler 2MW output 93% 93%* Single-boiler >2MW output 87% 88%* Single-boiler 84% 93%* Oil Boiler gross seasonal efficiency * not explicitly shown in ADL2 value shown as recommended by ADL2 clause 5.1 Table 3: Minimum boiler seasonal efficiency for heating systems in new buildings Fuel System Boiler gross seasonal efficiency Previous requirement Natural gas LPG Oil ADL2 2021 Single-boiler 400kW output 84% 91% Single-boiler 401kW2MW output 84% 88% Single-boiler 2MW output 85% 93% Single-boiler >2MW output 85% 88% Single-boiler 86% 93% Table 4: Minimum boiler seasonal efficiency for boiler systems in existing buildings Fuel System Previous requirement ADL2 2021 Natural gas New, direct >30kW 90% 91% New, direct 30kW 73% 91% Existing, direct 73% 91% New and existing indirect 80% 91% New, direct >30kW 92% 92% New, direct 30kW 74% 92% Existing, direct 74% 92% New and existing indirect 81% 91% Existing, direct 86% No option New and existing indirect 75% No option New and existing indirect 82% 91% LPG LPG Oil Boiler gross seasonal efficiency Note boiler efficiency boiler efficiency boiler efficiency Table 5: Minimum thermal efficiencies for new and existing domestic hot water (DHW) systems so, cannot claim any benefit from envisaged enhancements to the heat network. When considering a boiler installation in a new building, the boiler seasonal efficiency is required to be at least as high as listed in ADL2 (as shown in the abbreviated list of Table 3), which have incremental uplifts compared with the previous versions of the ADs. When replacing existing boilers, the requirements have a significant uplift, compared with those previously scheduled (in the 2013 NonDomestic Building Services Compliance Guide for England), as shown in Table 4; they are now practically all in line with those required for new buildings. This effectively means that, in normal applications, non-condensing boilers will not meet the requirements and cannot be installed in new buildings, nor as replacements. If the replacement employs a different fuel, it should not produce more CO2 50 July 2022 www.cibsejournal.com CIBSE July 22 pp49-52 CPD 199.indd 50 24/06/2022 15:47