Low-temperature district heating (LTDH) with target supply and return temperatures of 55°C and 25°C can help to improve the energy efficiency of the district heating grid and achieve a more sustainable energy system. However, concerns about the reproduction of legionella bacteria in the domestic hot water (DHW) heated by the LTDH provides a challenge.

Legionella bacteria commonly exist in both natural and manufactured aquatic ecosystems. Most countries have a required operation temperature for the DHW system – mostly above 55°C – to prevent the reproduction of legionella. In terms of the district heat- (DH-) supplied hot water system, the rules on operating temperatures may well be stricter, considering the temperature drop throughout the distribution network.

The potential options to ensure legionella-safe conditions can be divided into two categories: alternative designs of the DHW system and sterilisation treatments.

Alternative designs for water supply systems

The LTDH-supplied DHW system should be able to deal with the main risk factors of legionella proliferation – insufficiently high temperatures and extended periods of stagnancy. The alternative design method focuses on boosting the local temperature and minimising the volume of domestic hot water.

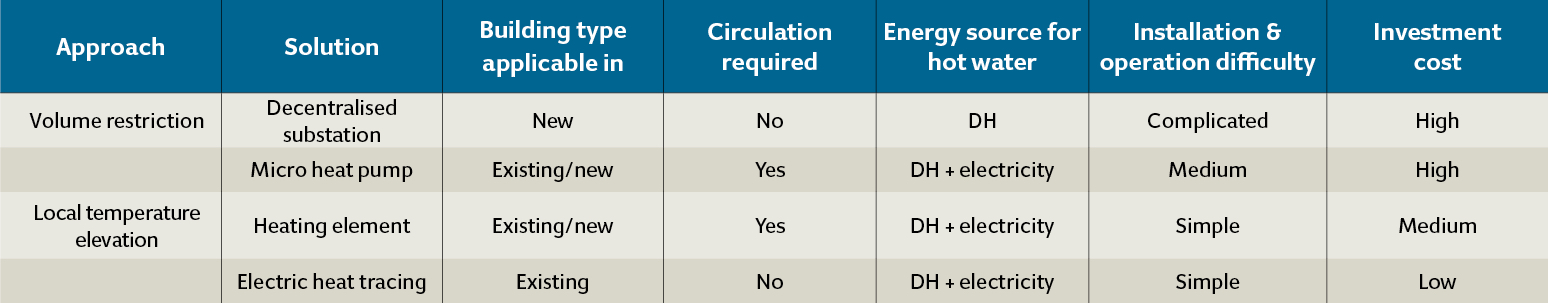

Table 1: Evaluation of the alternative design methods

Decentralised substation system

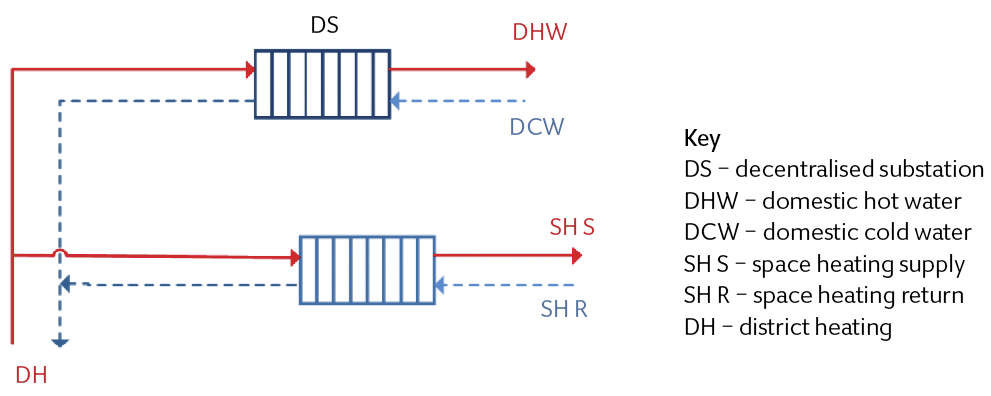

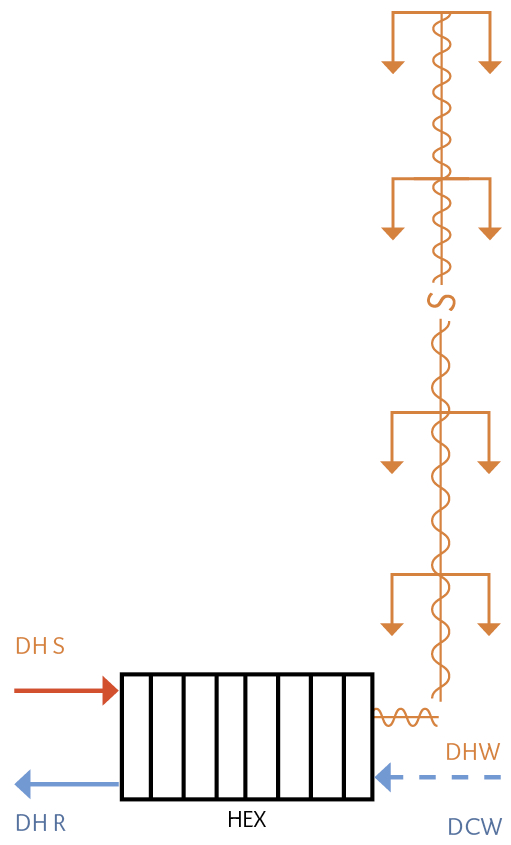

The main component of the decentralised substation system is the instantaneous heat exchanger unit installed at each home. It is designed to meet both the space-heating and DHW demand.

Unlike the centralised system, the decentralised substation option heats DHW locally, so minimises the total DHW volume. The energy efficiency is also improved by avoiding unnecessary heat loss.

Figure 1: Schematic of decentralised substation system

Micro heat pump

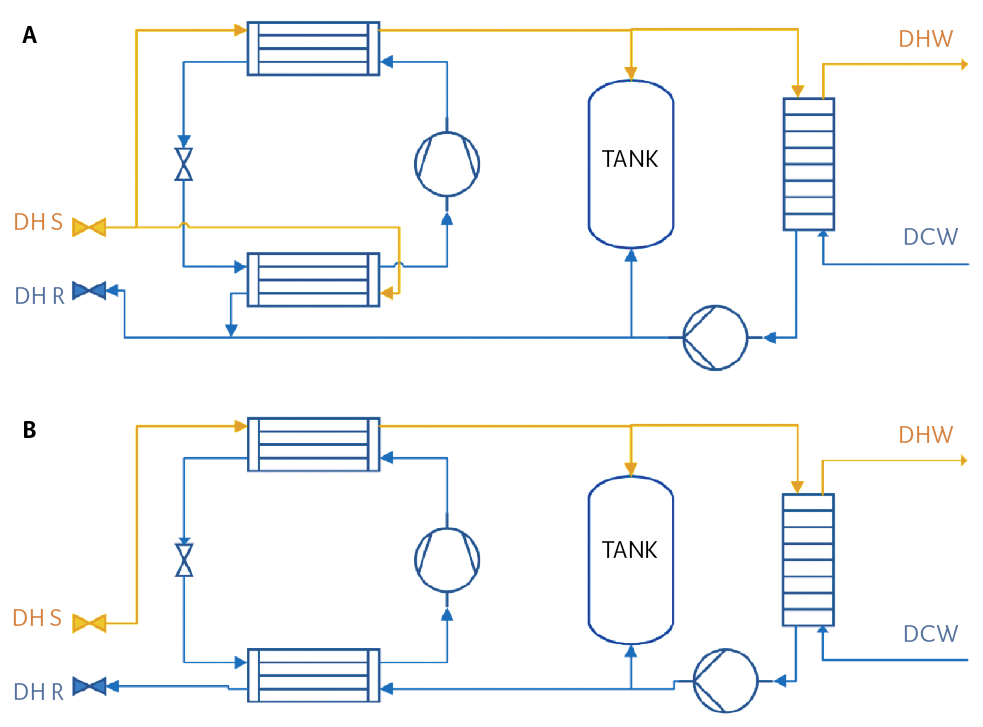

The micro heat pump system uses a micro heat pump unit to elevate the DH supply temperature. The heat source can be from either the DH supply or the return, depending on the installation.

The DH supply temperature can be more flexible with the heat pump, and a wider range of low-temperature heat sources can be considered. Also, the DH return temperature can be reduced if configuration b (Figure 2) is applied, which helps improve the energy efficiency of the DH system. However, this will reduce the coefficient of performance (COP) of the heat pump because of the greater temperature difference.

Figure 2: Schematic of micro heat pump system with DH supply flow as heat source (A) or DH return flow as heat source (B)

Electric supplementary heating

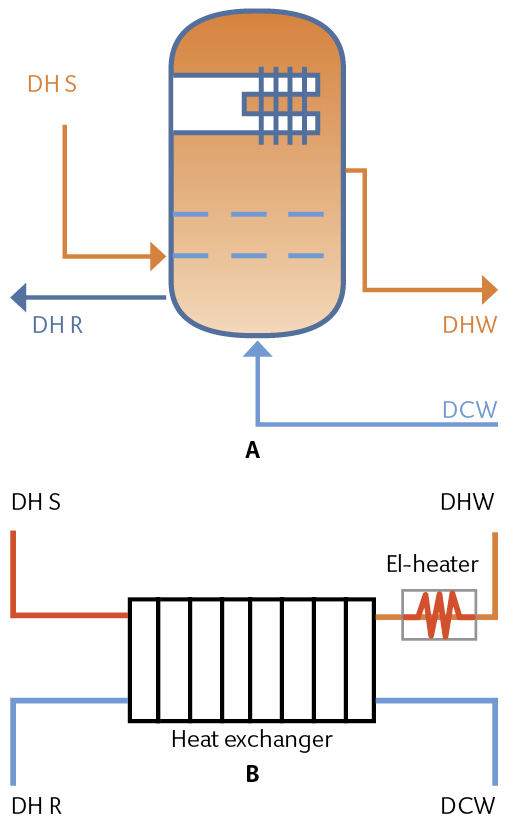

This system is also based on temperature elevation and the specific implementation will depend on whether a storage tank is installed. The storage type can help to reduce the peak load in the DH grid. However, there will be more heat loss compared to the direct electric heater because of the storage tank, with the set-point temperature of the consumer’s storage tank >60°C to prevent legionella.

Another type of electric supplementary heating is electric heat tracing. The electric heat tracing cable attached to the DHW supply pipe is used to heat DHW to the required temperature after being preheated by LTDH. A storage tank – and potentially domestic hot water recirculation – would not be required for such a system. For large hot water systems, the electric heat tracing option can save almost 30%1 of distribution heat loss caused by circulation.

Evaluations of the alternative designs and suitable building types for implemention are listed in Table 1.

Figure 3: Schematic of electric supplementary heating system (A) storage type and (B) direct type

Figure 4: Schematic of electric heat tracing solution

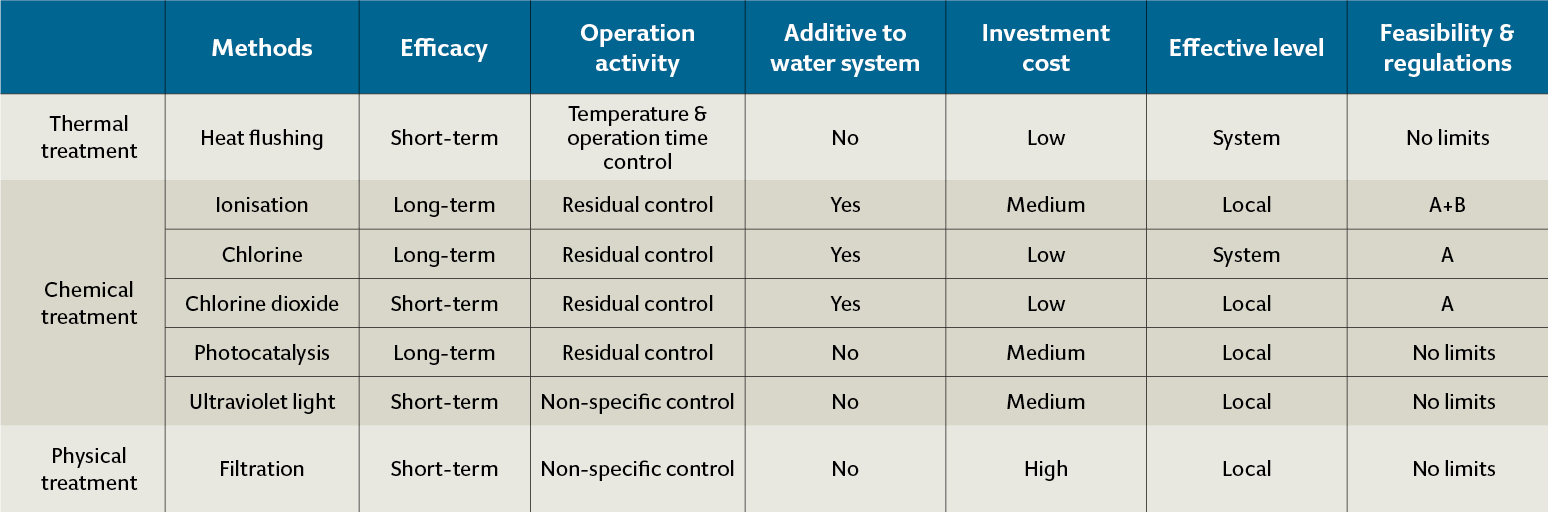

Sterilisation methods

These can be divided into three categories: thermal treatments, chemical treatments, and physical treatments. Any sterilisation method should meet the local requirements for water quality and water regulations, and work stably in the hot water system.

Thermal treatment

L. pneumophila in water can be killed by high temperatures, with the time required to do this related to the temperature – for example, 70°C for 10 minutes and 60°C for 25 minutes.2 Note, however, that even these high temperatures will have limited efficacy on any biofilm.

Careful planning and execution is required to make sure the required temperature can reach the end of every branch in the system.

Chemical treatment

Chemical treatments kill legionella by either injecting chemical agents – such as ionisation, chlorine or chlorine dioxide – into the water, or activating the oxidisation as if by sunlight (UV light, photocatalysis). The use of chemical biocides requires meticulous control to maintain effective concentrations without violating water quality requirements.

Physical treatment

This mainly refers to membrane filtration, which prevents the micro-organisms from getting into the protected system. Physical treatment can work effectively; however, to maintain the high efficacy of the filter, it has to be replaced regularly.

The evaluations of different sterilisation methods are listed in Table 2.

Table 2: Evaluation of the different sterilisation methods

A = the concentration of the agents must comply with local water-quality regulations

B = not applicable in some countries

Conclusion

This study has suggested several solutions for preventing the potential risk of legionella in the LTDH-heated hot water system. From the alternative system design methods, the decentralised substation option is recommended for new buildings because of the high energy efficiency. For existing buildings, electric supplementary heating is recommended, because it is more flexible with the DH supply temperature and simpler to install. When it comes to sterilisation methods, the chemical treatments are more economical, but should be operated meticulously, following water quality regulations.

Further details

The full paper, A study that considered the available methods of supplying safe domestic hot water using heat from a low temperature district heating system, is available in BSERT. CIBSE members always have free access to the online BSERT edition through the CIBSE Knowledge Portal.

References:

- Yang X, Li H, Svendsen S, ‘Modelling and multi-scenario analysis for electric heat tracing system combined with low temperature district heating for domestic hot water supply’, Building Simulation, 9 (2016), DOI: 10.1007/s12273-015-0261-4.

- Stout JE, Best MG, Yu VL, ‘Susceptibility of members of the family legionellaceae to thermal stress: Implications for heat eradication methods in water distribution systems. Applied and Environmental Microbiology, August 1986, 52(2), 396-9.

- Xiaochen Yang, Hongwei Li and Svend Svendsen, civil engineering department, Technical University of Denmark. Email xiay@byg.dtu.dk