The Orchard Centre could reduce its environmental impact by 6% to 7% by implementing the study’s recommendations

Approximately 10% of all UK carbon emissions are associated with the manufacture and transport of construction materials. These emissions are all upfront, contributing towards global warming before the building is opened. Yet measuring embodied carbon has often been thrown in the ‘too hard’ basket because of the difficulty in obtaining transparent and comparable data, and to implement consistent and auditable frameworks and processes within a reasonable budget. There is also a lack of policy drivers to measure and control embodied emissions in building projects.

However, European developer Hammerson has measured embodied carbon to inform the design processes on a new retail development in the UK – and used a cost-effective tool to do so. Hammerson plans to add to its portfolio of 58 UK, Irish and French shopping centres and retail parks, with an extension to the Orchard Centre in Didcot, Oxfordshire. The proposed scheme is targeting a ‘very good’ Breeam assessment and has a number of sustainable design principles, including an urban drainage scheme and a green roof.

To increase its chances of achieving a ‘very good’ rating, Hammerson has – for the first time – used Impact modelling to calculate the environmental impact of the proposed development, to achieve credits under the MAT01 Life-cycle impacts assessment issue. Impact is a specification and database for software developers to incorporate into their tools, to allow consistent life-cycle assessment and costing in property. It takes quantity information from building information modelling (BIM) and multiplies this by environmental impact and/or cost ‘rates’. It is based on the BRE database on environmental impacts and, by making this more widely available, the costs of embodied-carbon assessments are significantly reduced. It was also developed with integration into Breeam in mind.

Impact and building services

To carry out a building life-cycle assessment (LCA), background data – known as an environmental product declaration (EPD) – is required for each of the products/systems ultimately specified, and for the alternatives considered during design process. The resource needs to be in a format that is useful to building designers. In the UK, this exists for building fabric in the shape of BRE’s Green Guide and, more recently, Impact tools – but unfortunately according to BRE’s Dr Flavie Lowres, an associated director in the sustainable product group, there is still not a lot of activity in the building service sector with regards to EPD. Although Lowres says in Europe, manufacturers such as Wildeboer Bauteile have had EPDs created for a: circular volume flow controller VRE and VR; volume flow limiter; and smoke control damper.

The lack of building services data may lead some LCAs to rely on assumptions about the constituent materials of various components/systems – so results derived from this kind of approach are likely to have a high degree of uncertainty. Many components are complex and highly engineered from a wide range of substances, and sourced from a complex international supply chain. Without intimate production knowledge, it is very difficult to make estimates with any certainty.

As the use of poor-quality data will still yield results, this could serve to delay the realisation by the industry of the need for good-quality data. As such, BRE believes it is preferable to exclude services from LCAs until a robust source of building services LCA data/EPD is available.

In the last 12 months, BRE has been working on the development of a tool that allows non-LCA experts to carry out LCA for the purpose of getting an EPD, and this includes building services. The tool is called LINA and was launched in June 2016. More info can be found at http://www.bre.co.uk/lina

Using it can gain up to four credits for UK Breeam assessments and up to six credits for international Breeam assessments.

Richard Quartermaine, environmental manager at Hammerson, says the company wants to make significant reductions to all areas of its carbon footprint, and the least well understood is the embodied carbon of its development activities. ‘Using Impact allows us quickly and consistently to assess the embodied carbon of a project at an early stage – to raise awareness among the design team and inform its decision-making.’

Envision is undertaking the Breeam assessment for the project, and Andrew Cooper CPEC (now merged with EVORA) has been appointed to do all the Impact modelling using IES VE Pro. An energy model was developed by the building services engineer using IES VE software. This was used for the energy strategy, to comply with Part L and to calculate Breeam energy credits. The model was also issued to the Impact modeller to undertake the life-cycle impacts assessment using the same software.

Product life-cycles

‘Cradle to gate’ is an assessment of a partial product life-cycle from resource extraction (cradle) to the factory gate, covered by Modules A1 to A3 as described in BS EN 15978:2011 Sustainability of construction works — Assessment of environmental performance of buildings — Calculation method. This captures the environmental impact from the product life stage (pre-construction).

‘Cradle to grave’ is the full life-cycle assessment from resource extraction (cradle) to use phase and disposal phase (grave).

The first task was to check the suitability of the model for an Impact assessment. Models must be constructed using the ApacheSim (DSM) format – in Energy Performance Certificate (EPC) terms, this is considered to be Level 5. The geometry must also be extremely accurate; discrepancies that may have a minimal impact on the built emissions rate (BER) could have a significant impact on a life-cycle assessment by affecting material quantities. For example, if the height of each floor of a 10-storey building with a floor plate of 1,000m2 is 25mm out in a model, this is unlikely to have a significant effect on predicted energy consumption or the BER. But 10 x 1,000m2 x 0.025m equates to 250m3 of material. Assuming the floors are concrete, the concrete alone would amount to around 100 tonnes of embodied CO2 as an inaccuracy. Add steel reinforcement and/or steel decking to this, and the amount increases.

Having assessed the model, and made minor adjustments to ensure its suitability, a study was implemented to identify the construction details and materials. Material data was imported from the BRE library into the model. The scope of the study covered the mandatory building elements detailed in Breeam Assessor Guidance Note GN08, which include piled foundations, lowest floor construction, steel frames, all upper floors, roofs, windows, and internal walls and partitions. Having determined the environmental impacts, an advisory report was prepared for Hammerson.

The software can measure a number of environmental impacts, including acidification of land and water, fossil-fuel depletion, human toxicity, and global warming potential. In this case, the primary metric that Hammerson wished to adopt was embodied CO2, and benchmarking was used to advise on whether the proposed scheme had a high or low impact.

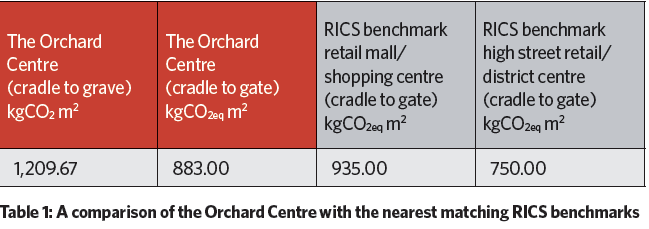

Monitoring the embodied carbon emissions of different types of buildings is a relatively new field of research, and there are not yet regulatory standards or academic studies offering peer-reviewed benchmark values. However, the RICS document Methodology to calculate embodied carbon of materials, 1st edition provides some useful benchmarks for cradle-to-gate embodied carbon emissions. The MAT01 study is based on cradle to grave – and the RICS benchmark is regarded as indicative only – but, for completeness, metrics were supplied to Hammerson for cradle-to-grave and cradle-to-gate emissions. (See panel, ‘Product life-cycles’.)

The study concluded that the impact of the Orchard Centre is within an expected range, based on the nearest matching RICS benchmarks of between 750 and 935 kg CO2 per m2 for comparable buildings (Table 1). It recommended interventions that could lead to a reduction in the project’s environmental impact of between 6% and 7% – amounting to more than 1,000 tonnes of embodied CO2.

Andrew Cooper is a director at Evora Edge