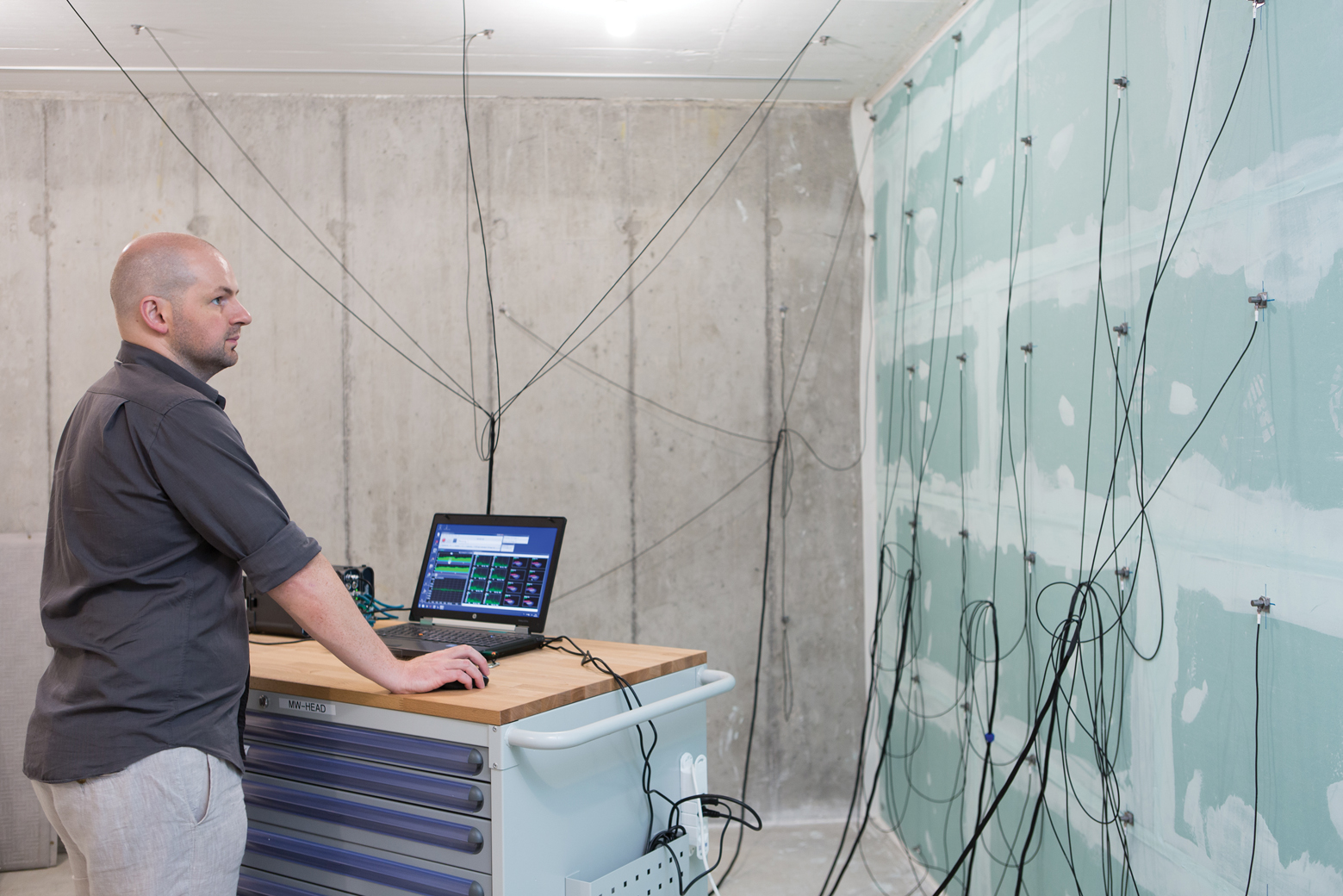

Sound equipment measuring drainage noise from behind a wall at Geberit’s Switzerland acoustics lab

Last year, CIBSE updated its guide covering noise and vibration control for building systems. The document, known as CIBSE Guide B4, offers advice on the generation, prediction, assessment and control of noise and vibration from building services. It aims to ensure designers produce systems that meet acceptable noise limits and the requirements of aerodynamics, energy use and economics.

The guide summarises some of the main problems that can arise from heating, ventilation and air conditioning (HVAC) systems, and gives an overview of the frequency characteristics of the main noise sources, before describing the various sound transmission paths to receivers and how they may be controlled. This is followed by a detailed description of the various noise sources arising from building services provision: fans; variable air volume (VAV) systems; grilles and diffusers; roof-top units; fan coil units; chillers, compressors and condensers; pumps, motors and standby generators; boilers; chilled ceilings (active and passive); cooling towers; and lifts and escalators.

Detailed information about noise-emission data – enabling typical values of sound pressure and sound power levels to be estimated – is given in this section. This information will be of use to the designer in the early stages of design, before manufacturers’ test-based data is used in the final design stage.

There are further sections on:

- Noise control in plantrooms

- Mechanisms of airflow-generated – or regenerated – noise in ducts

- Prediction and control of noise transmission in ducts and fittings

- Predicting and controlling sound levels in rooms, and the effects on speech interference and privacy

- Noise transmission to/from outside in naturally ventilated buildings

- Criteria for the assessment of noise in building services systems

- Worked examples of the prediction of noise levels within rooms and at external receptors

- Fundamentals of vibration, vibration control and practical aspects of vibration isolation.

Noise from waterflow systems

Although much of the CIBSE guide deals with noise from HVAC systems, section 4.3.19 addresses noise from waterflow systems, including all water-supply and wastewater systems.

Pipework and components in waterflow systems radiate airborne noise, which must be considered. However, noise can also be radiated by building elements – for example walls and floors – because these services are structurally attached to them.

To reduce noise throughout sanitary systems, the important thing is to study every aspect of the noise chain

This applies not only to appliances, such as pumps and cisterns, but also to pipework. So the type of pipework can be important, as can considering whether equipment appliances and pipework should be isolated from the building structure. Noise in waterflow systems may be minimised by: good choice of equipment and pipework; careful installation to ensure smooth water flow; avoidance of excessive flow velocities; isolation to prevent excitation of the building structure; and good equipment maintenance (see panel, ‘Minimising noise in waterflow systems’).

Noise from chillers

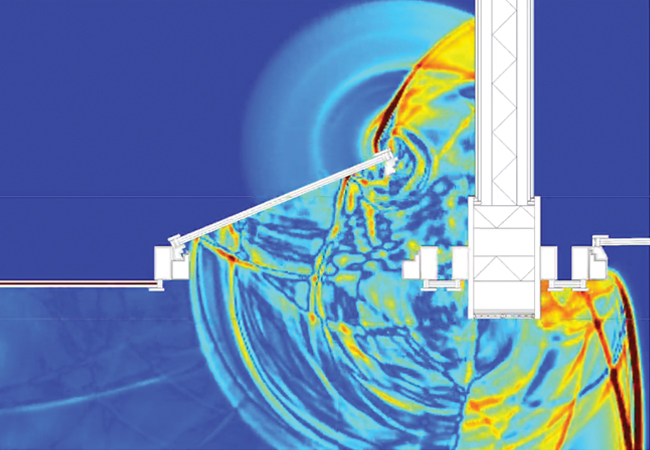

Chillers produce tonal and broadband noise. The evaporator and condenser elements of chillers usually display different acoustic characteristics. Noise from the evaporator is often composed of tonal noise, typical of that from rotating or reciprocating machinery, linked to the rotational frequency. Broadband noise is also present, generated by either liquid or gas-fluid flow. The tonal noise tends to be dominant – perceived as a whine or whirr – but the frequency range depends on the mode of operation.

Noise from the condenser is usually broadband and dominated by fan noise, although variable-speed fans do much to control the impact of this when the equipment is not operating at full load.

Air-cooled chillers combine these sources in a single unit, enabling bespoke noise-control packages of different sizes to be considered, depending on the acoustic attenuation required. Locating the evaporator in a plantroom will remove this external noise source and, usually, reduce the noise emission from the chiller’s external elements.

Ultra low-sound chillers

Acoustic attenuation towers being installed for Berkeley Homes

Aecom’s sound specification required a limit of 51dBA at 10m. In standard format, the chillers were rated at 63dBA at 10m. To achieve the 12dBA reduction, the design had to be re-engineered, and acoustic attenuation towers were added to both sides of each condenser fan, making an upper array of 16 towers per chiller. Measuring 1.6m high and 1m in diameter, each tower is lined with lead-damping material and a perforated liner to absorb sound. The condenser fan is positioned at the midpoint, providing attenuation at both the air inlet and discharge sides.

A bull-nosed column in the tower further reduces turbulence, while sickle-bladed, low-noise fans help streamline airflow. The compressors are housed in acoustic enclosures, reducing sound from this source by 6-7dBA. Finally, refrigerant discharge lines from compressors to condenser are lined with lead insulation, further reducing vibration.

Guide B4 gives example noise levels from different types of chillers, although use of manufacturers’ noise-level data – based on standard test procedures – is always preferred.

The document concludes with a summary of the guidance on noise and vibration, eight appendices, a glossary of terms, and a list of reference material.

Minimising noise in waterflow systems

Acoustic measurements are taken using acceleration sensors at Geberit’s laboratory

Jonathan Briafield, Geberit’s product manager for piping systems, says building acoustics has to be considered at the design stage to ensure bathrooms are located above other bathrooms or kitchens, rather than bedrooms and other noise-sensitive areas.

It is also critical to consider the location of appliances within the installation room. Wall-mounted toilets and washbasins are more acoustically beneficial than floor-standing equivalents because their frames are fixed to the structure of the building, while noise-reducing studs can further minimise noise transmission into the frame.

A rubber or foam seal between the toilet and wall can also reduce the transmission of vibrations from a flush or a dropped toilet seat.

Pipe materials should be considered too. Cast iron is best at reducing airborne noise, and many ‘silent’ pipes have made their way onto the market, says Briafield.

‘But cast iron pipes are very expensive, have a big environmental impact in production, and the rigid bracketing that fixes them to buildings can also transmit vibration into the structure,’ he adds.

Where vertical stacks are impossible, designers should minimise pipe offset angles – where noise is amplified – as well as use rubber-buffering and rubber-lined bracketry on pipes to alleviate vibration transmission.

‘To reduce noise throughout sanitary systems, the important thing is to study every aspect of the “noise chain” and reduce sound all the way through,’ says Briafield.

He adds that if designers use all of the above mechanisms, they can get noise levels down to 25dB in bedrooms – which is much lower than the UK benchmark level of 45dB in living rooms.

- Bob Peters is principal consultant at Applied Acoustic Design and chair of the Guide B4 steering committee

- Guide B is available to download at the Knowledge Portal