The provision of good-quality ventilation to a school is required to ensure that the internal environment is comfortable and conducive to effective learning. Traditionally, UK schools have been designed with large, opening windows and appropriate room aspect ratios to enable the properly educated user – often the teaching staff – to maintain reasonably ventilated conditions. However, because of their siting or use, many new or refurbished schools will require part, or full, mechanical ventilation – together with heat recovery – and it is important that such systems have life-cycle performance that provides effective, energy-efficient operation.

This CPD will consider the recently updated standards that determine the requirements for ventilation in teaching spaces; the drivers for applying mechanical ventilation; and how equipment certification can provide essential evidence that mechanical ventilation products are fully fit for use.

As discussed in the recently published CIBSE TM57 Integrated school design, a poor internal environment can affect the performance of both teaching staff and students. The principles for a ‘good quality’ environment require that the internal contaminants are appropriately diluted with outdoor air, the spaces are neither overheated nor too cold, and that there is reasonable air movement, with an absence of cold draughts. The location of modern schools, the density of occupation and the associated heat gains and CO2 produced by the occupants may not always be conducive to the application of natural ventilation, so suitable mechanical methods are often required.

There is a good amount of guidance available to the designer to assist in the design and selection of appropriate ventilation methods. In the UK, the Education Funding Authority (EFA) produces the baseline requirements for schools and sets the standards under the Priority School Building Programme.1 The guidance, including BB101 Ventilation of school buildings and BB93 Acoustic design of schools – performance standards have evolved in recent years to meet current expectations and reflect improved understanding of the impact of internal environmental quality on teachers and students.

ClassVent2 and ClassCool2, the freely available calculation tools that may be used to undertake simple modelling, are now recommended for early assessment stages and – although still useful – are no longer promoted as Building Regulation compliance tools. ClassVent produces preliminary sizes for ventilation openings for a variety of ventilation strategies, and ClassCool can be used at the early stages of design to consider ways to prevent summertime overheating.

The EFA ventilation design standards have recently been updated in the form of the Baseline designs ventilation strategy3, to meet the recommendations of CIBSE TM52 The limits of thermal comfort: avoiding overheating in European buildings and follow the guidance of CIBSE KS16 How to manage overheating in buildings.

The EFA plans to update BB101 this year with new guidelines for ventilation, thermal comfort and indoor air quality so that it reflects standards in the 2013 edition of the Facilities (Services) Output Specification4 and the associated ventilation strategies. The UK Building Regulations documents refer to BB101 as being an acceptable means of meeting the energy efficiency and legislated ventilation requirements.

When assessing the risk of overheating, the updated requirements consider adaptive comfort (as per EN152515) and apply operative temperature – accounting for radiant and air temperatures – as well as considering the variability in outdoor temperature.

The measure of indoor air quality, in terms of maximum CO2 levels under any conditions, is now set at 1,500 parts per million (ppm) for mechanical ventilation, and 2,000 ppm for natural ventilation for no more than 20 minutes during the school day. Operationally, the normal target is 1,000 ppm for mechanical ventilation and 1,500 ppm for natural ventilation. The rationale for this is that CO2 level, in the absence of any other major pollutants, is a reasonable indicator of ventilation performance for the control of indoor air quality in an occupied building. In any case, an increase in normal CO2 levels has been associated with poor performance – potentially having an adverse effect on the productivity of pupils and teachers.

There are many other contaminants, both particulate and gaseous, that will affect indoor air quality in schools. Some pollutants will be generated through indoor activities such as cooking (particles, carbon monoxide, nitrogen oxides) and cleaning (volatile organic compounds [VOCs]), while others are emitted from building, furnishing and consumer products – such as carpets, adhesives, paints, houseplants and toiletries – particularly when they are new. Some of these, and particularly particulates (for example, PM2.5), may well be introduced into the space through unfiltered outdoor air infiltration and ventilation.

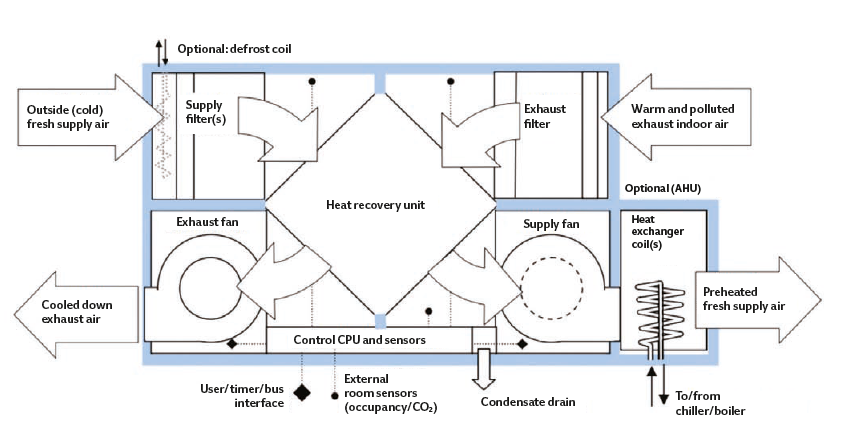

Figure 1: An example of a typical MVHR unit8

BB93 section 1 was very recently updated, superseding the previous version and the 2013 Acoustic Performance Standards for the Priority School Building Programme, as well as the acoustic requirements of BB101. It now provides the performance required for compliance with Part E4 of England and Wales Building Regulations – Acoustic conditions in schools. Acceptable background noise levels in teaching and learning spaces are defined by the tabulated values of design ‘indoor ambient noise level’ (IANL) to ensure clear communication of speech between teacher and student – and between students – and to allow learning and study activities. If a room is naturally ventilated, the IANL is calculated and measured with ventilators or windows open, as required to meet the ventilation standard. If a room is mechanically ventilated or cooled, the plant is assumed to be running at its normal operating duty.

A design guide is set to accompany the new BB93 in the near future.

Meeting the ventilation need

Traditionally, natural ventilation has been a preferred route to meeting the ventilation needs of schools, employing operable windows and trickle vents or other purposemade openings. Although natural ventilation may be the right option for appropriately designed new-build projects, it is very likely that many refurbishment projects and some new buildings will require different thinking.

As illustrated in the research underpinning the EU EcoDesign Directive on airconditioning and ventilation7, mechanical ventilation can often provide a more suitable solution for modern buildings that meet local building codes. The reasons cited were:

• Excessive heating loss in natural ventilation (caused by limited opportunity for heat recovery)

• A healthy indoor climate for the inhabitants can no longer be guaranteed without mechanical ventilation – for example, to achieve adequate levels of ventilation, windows may need to be opened wide for long periods of time, creating additional noise pollution and security issues

• Comfort – for example, inhabitants will not tolerate the cold draughts from natural ventilation, and by blocking air intakes (to reduce draughts) they can create an increasingly unhealthy living environment

• Mechanical ventilation was determined as being economically attractive. For example, in modern well-insulated dwellings, the natural ventilation heat losses can make up more than half of the heat losses.

By considering a number of scenarios – and even applying optimistic values for natural ventilation – the analysis showed payback periods for the mechanical equipment to be well within its operational life.

However, as demonstrated in CIBSE TM57, there are also many applications where natural or hybrid ventilation systems can work effectively in northern European applications.

Application of mechanical ventilation and heat recovery in schools

Mechanical ventilation and heat recovery (MVHR) systems (as illustrated in Figure 1) are already often applied where effective natural ventilation is not possible, or as part of a hybrid system. MVHR works by extracting vitiated air from inside the school and replacing it with outdoor air. At times of heating need, the system utilises heat from the outgoing air to warm incoming air, via an air-to-air heat exchanger mounted within the MVHR unit.

By January 2016, to meet first-tier EcoDesign requirements for non-residential ventilation units (EU regulation 1253/2014), all such units will also include a ‘thermal bypass unit’ that will operate when heat recovery is not advantageous, such as in summer and times of high room heat gains, where the ventilation is used to provide ‘free’ cooling.

Modern MVHR systems are capable of recovering 85% of thermal energy, and can readily adjust automatically to changing demands within a room. For example, presence detectors may be used to switch the system on when the room is occupied and off again when it’s empty, while CO2 sensors can be applied to adjust the air supply proportionally to the number of people in the room. This is particularly useful in areas with transient occupation, such as gyms, that are often populated for a few hours during the day and will, otherwise, utilise a continuously running heating and ventilation system.

When appropriately specified and procured to meet relevant standards, MVHR can ensure new schools will meet Building Regulations and the EFA ventilation guidelines, while also improving the predictive energy ratings – Standard Assessment Procedure (SAP) and Energy Performance Certificate (EPC) – as well as the actual operational energy efficiency.

Assuring performance of MVHR products

The energy consumption of an MVHR unit is principally determined by:

• Temperature efficiency – how well it is able to recover heat

• The air velocity in the internal sections of the unit, and so the pressure drop, particularly through the heat recovery unit and filter(s)

• The efficiency of the motor, drive assembly and fan

• The effectiveness of the cooling and heating coils

• The liquid/fluid pressure drop through the heating and cooling coil

• Any effects caused by the installation of the unit.

However, neither BB101 nor BB93 explicitly identify which standards the manufacturers should follow. A reputable independent product certification process will include the testing of both the mechanical and performance characteristics so that it at least meets the required standards, as well as typically providing additional information that allows more meaningful life-cycle assessments. Such certification physically verifies that manufacturers’ data are correct through independent testing, and only certifies products if they meet the relevant European standards.

Mechanically, this would encompass testing to EN 18869, including such items as: casing strength; casing air leakage; filter bypass leakage; casing thermal performance; and acoustic insulation (by measuring sound insertion loss).

The operating performance, tested as specified in EN 1305310, would include: available external total pressure; air volume flow rate; electrical power input to the fan motor; heating and cooling coil output; coil pressure losses on the liquid side; heat recovery and air leakage between air streams in the heat recovery device; and duct and casing emitted sound power levels. The performance of some component parts, such as fans and filters, are assured by crossreferencing of EN 13053 with other relevant standards. Others, such as humidifier sections, have specific performance tests included in the standard.

Figure 2: An example of an MVHR unit that is constructed to meet appropriate standards (Source: Fläkt Woods)

The appropriate calculation and assessment method for ‘specific fan power’ (SFP) necessary to comply with local codes is included in EN 13779.11 This standard also identifies that a filter grade ‘F7’ (or MERV13) results in ‘moderate’ IAQ (99% arrestance and 80-85% efficiency). In some MVHR units, the filtering effectiveness has been compromised by using coarse filters such as G4/MERV6 (90-95% arrestance and 20-30% efficiency) to reduce their SFP. G4 filters provide IAQ that can be below that defined as low IAQ in EN 13779.

So an independent product-testing and evaluation process (such as that provided by BSRIA) will assure relevant standards so that MVHR units (such as the unit in Figure 2) are directly comparable, including relative lifecycle appraisals. Such systems can provide an effective solution, both independently and in hybrid systems, to ensure a well-ventilated and productive school environment with a low life-cycle cost.

© Tim Dwyer, 2015.

With thanks to Mark Ferris of Elco, who has provided the practical applications used in this article.

Further reading:

For a more extensive discussion of the requirements for ventilation in schools, comparison of design solutions and case studies, see the newly-published CIBSE TM57.

References

- 1. UK Government Priority School Building Programme, www.gov.uk/government/collections/priority-school-buildingprogramme-psbp, accessed 4 May 2015.

- 2. ClassVent and ClassCool: school ventilation design tool, www.gov.uk/government/publications/classvent-and-classcool-schoolventilation-design-tool, accessed 4 May 2015.

- 3. Education Funding Agency (EFA), Baseline designs ventilation strategy – December 2014, www.gov.uk/government/uploads/system/uploads/attachment_data/file/388149/Baseline_designs_ventilation_strategy_Dec_2014.pdf, accessed 4 May 2015.

- 4. EFA, Priority School Building Programme (PSBP), Services Output Specification – June 2013, www.gov.uk/government/uploads/system/uploads/attachment_data/file/276993/psbp_sos_june_2013.pdf, accessed 4 May 2015.

- 5. BS EN 15251:2007 Indoor environmental input parameters for design and assessment of energy performance of buildings addressing indoor air quality, thermal environment, lighting and acoustics.

- 6. Satish, U, et al, Is CO2 an indoor pollutant? Direct effects of low to moderate CO2 concentrations on human decision-making performance, LBNL 2012.

- 7. https://circabc.europa.eu/sd/a/eff114ed-8c66-4425-9824-8951f9c5947e/Lot%206%20ENTR%20Ventilation%20units.zip Task 6, Section 5, accessed 4 May 2015.

- 8. EC ENTR LOT 6, Final executive summary for ventilation systems.

- 9. BS EN 1886:2007 Ventilation for buildings – Air handling units – Mechanical performance.

- 10. BS EN 13053:2006 Ventilation for Buildings – Air handling units – Rating and performance for units, components and sections.

- 11. BS EN 13779:2007 Ventilation for nonresidential buildings. Performance requirements for ventilation and roomconditioning systems.