The application of low temperature hot water radiant heating in buildings can provide energy-efficient solutions that do not take up valuable floor or low-level wall area and, increasingly, can also offer quality assured integrated building services.

This CPD considers the underlying process that drives radiant heating, and discusses the application of simple and integrated service panels.

Thermal radiation

All real materials will radiate ‘heat’. Radiant thermal energy may be thought of as consisting of electromagnetic waves or tiny, massless particles of energy, known as photons. The molecular movements within a material are associated with electric and magnetic fields, resulting in the emission of photons, radiating energy through its surface boundary – as the temperature rises, the molecular movement increases and more radiation is transmitted. Science is still discovering phenomena associated with radiative heat flow that cannot be completely described by this depiction. However, it is perfectly adequate and, in practice far beyond the knowledge required for applications in building services engineering. Whether the energy is passing through a vacuum or the air in a room, it will move at the speed of light, so providing an instantaneous source of heat that is available as soon as the emitter temperature is at a temperature higher than that of the receiving surface.

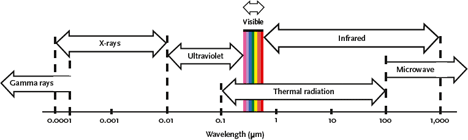

The temperature of a surface will affect the emitted electromagnetic frequency. At high temperatures – such as that of a ‘red hot’ coal fire or an electric bar fire – incandescence will make the flow of energy visible. At temperatures typically found in a building’s HVAC system, the frequency will be lower and the wavelength will be such that it is no longer visible to human eyesight – known as the infrared (‘below red’) region, as shown in Figure 1. All objects will emit a spectrum of radiation, and even extremely hot surfaces that have the peak of their emissions at a high frequency, short wavelength (such as the sun, at a temperature of above 5,500K) will still emit most energy in the infrared region.

Figure 1: Electromagnetic spectrum

The surface temperature of low temperature hot water (LTHW) radiant heating panels is typically between 30°C and 70°C, so emissions are predominantly within the infrared region. These cannot be seen with the naked eye but, using an infrared-sensitive camera, the profile of the temperatures may be visualised. Figure 2 shows a free-hanging LTHW radiant heating panel under test, with its corresponding infrared thermal image.

The amount of available heat energy will be related to the absolute temperature difference of two objects to the power of four (that is,ΔT4). This compares with convective and conductive heat flow, where the driving force is related approximately proportionally to the temperature (that is, ΔT1). So, particularly at higher temperatures, the radiant heat transfer component will dominate the heat flow. At lower temperatures – as typically encountered in buildings – small changes in temperature difference can more significantly alter the magnitude of the radiant, compared with convective, heat output.

The actual amount of energy received is dependent upon the temperatures, emissivities, absorptivities and mutually viewable surface areas of two objects – such as a ceiling mounted LTHW radiant panel and a floor. The ability to emit and receive radiant energy (‘emissivity’ and ‘absorptivity’)will depend on the materials, their shape and surface finish. The values will vary with frequency and are compared to the values fora theoretical ‘black body’ that has an emissivity and absorptivity of 1 (a perfect absorber). A polished silver surface has an emissivity of about 0.02 at room temperature, whereas black soot has an emissivity approaching 1, so soot may be used as approximating an ideal ‘black body’. Apart from those extremes, the human eye is not good at judging specific values of emissivity. To analyse the radiation performance of systems requires detailed knowledge of the spectral (frequency-related) and directional radiation characteristics.

Electromagnetic radiation only delivers thermal energy when absorbed by another material; no energy is lost when passing through a vacuum and very little through air. When striking a material, the energy will be absorbed, reflected or transmitted (that is,passed through). If, for example, the photons strike a perfectly reflecting mirror, then no energy would be released. However, building materials (and building occupants) will perform somewhere between the theoretical ‘black body’ and a reflector. In practice, most non-metalised finishes in buildings (and people) have an emissivity of around 0.9. For example, a white enamelled radiant heater would typically have an emissivity of 0.95.

It is the exchange of energy between two bodies – rather than the absolute value of an object’s heat radiation – that is of interest in building heating systems. An advantage of radiant transfer is that more energy is delivered if the temperature difference between the bodies is greater – hence, radiant heating could be thought of as self-balancing the heat flow to where it is required. For example, an external wall might have a lower surface temperature than an internal wall, so more energy would be exchanged to that than to warmer surfaces (the amount will depend on the position and surface characteristics of the materials).

Operational radiant heating

A greater contribution from radiant heat to an occupied space means that a lower air temperature is acceptable, while providing the same comfort levels. If properly controlled, this can result in energy – and cost – savings.

This may be readily illustrated using the CIBSE simple model1 for sizing heat emitters, where a radiant component fora ceiling mounted panel can be in excess of 0.6, compared with a convector radiator with a radiant component of 0.1. Effectively, by increasing the average temperature of a room’s surfaces – the ‘mean radiant temperature’ – the required air temperature is reduced while maintaining the same ‘mean operative temperature’ (a function of air temperature, mean radiant temperature and air velocity). The value of mean radiant temperature varies in a room, depending on the surrounding temperature, emissivity and ‘shape factor’ – the fraction of radiant energy leaving one surface that is intercepted by another surface. Practically, for forensic purposes, the mean radiant temperature felt by an occupant at any particular point in a room may be measured with a globe thermometer mounted 1,140 mm off the floor.2 For operational control, it is important that the room sensors are able to take account of both radiant and air temperatures, and that they are positioned appropriately – as discussed in the CLIMA 2007 paper by Simone et al.3 The term ‘black bulb sensor’ is often used for such a device.

For ‘normal’ room conditions (with an air velocity less than 0.2 m·s-1), the operative temperature, θc (°C), is simply the average of the mean radiant temperature, θr (°C), and the room air temperature, θai (°C). However,if it is expected that air velocity is likely to behigher, then θc = A θai + (1-A) θr, where A is determined depending upon local air velocity, va (m·s-1), where A = 0.5 if va < 0.2 m·s-1, A = 0.6 if 0.2 m·s-1 < va < 0.6 m·s-1,A = 0.7 if 0.6 m·s-1 < va < 1.0 m·s-1. So as va increases, the relative influence of the radiant temperature on comfort will reduce.

However, increased air changes will have less impact on the performance of radiant panels compared with convective systems, since the radiant component is unaffected by the air change rate, whereas convective systems must primarily raise the air temperature to maintain comfort conditions.This can provide an advantage for areas such as classrooms and lecture theatres (Figure3), where doors may remain open between occupied periods, allowing significant volumes of air to pass through the space.

Shorter pre-heat times are often associated with radiant systems, due to the radiant heat transfer exchanging heat directly with the building’s thermal mass. As soon as the radiant heating panel temperature is above that of the room’s surfaces the building fabric will begin to absorb heat. Radiant heating panels have a lower water content than traditional radiator systems, so heat-uptime is reduced, allowing more effective intermittent use. Low temperature hot water radiant ceiling-mounted heating panels will have a downward radiation component of approximately 60%. The remaining 40% is convected, maintaining the soffit temperature, and can prevent cold down draughts. Unlike shorter wavelength solar radiation that can pass through the glazing of a building, lower temperature, longer wavelength radiation from a radiant panel does not pass through glass, so can be used effectively in rooms with glazed façades.

Thermal comfort and air quality

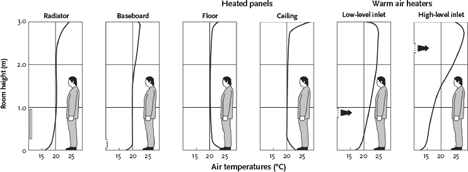

Thermal comfort is realised with appropriate air and mean radiant temperatures, and no excessive vertical air temperature differences, extreme temperature asymmetry, or excessive air movement. A properly designed and installed radiant heating system will directly transfer heat to surfaces and objects (such as walls and floors) and then heat the air in the occupied space through secondary convection. Since the floor provides secondary heating, the thermal gradient within the occupied zone (0.1m to 1.8m from the floor) is typically 0.5 K – CIBSE4 recommends a maximum of 3 K for general applications. The vertical temperature gradient for various heating types is illustrated in Figure 4.

Figure 4: Vertical air temperature gradients for different heating types (Source: CIBSE Guide A 2006)

A room with high ventilation rates or significant infiltration can still maintain reasonable operative temperatures with radiant heating, since the radiant input is unaffected by the volume of airflow. It is important, however, to ensure that any asymmetric temperature felt by the occupant does not cause discomfort – as a matter of appropriate design and installation.

Heating a room with radiant (rather than convective) exchange results in less air movement, so reducing entrained airborne particulates. Since the radiant panels are typically simple flat surfaces with no extended ‘finned’ sections, cleaning is more readily undertaken. These combine to provide conditions where the indoor air quality is potentially improved, compared with a convective-dominated heating system – making them particularly suitable for hospital and healthcare environments.

Building coordination and installation

As LTHW radiant panels are ceiling-mounted or free-hanging, they do not occupy valuable floor and wall space. And since radiant energy is not significantly affected by distance within a building, LTHW radiant panels can be used in areas with high-level ceilings – for example, atriums, lecture theatres and sports halls – without special consideration for the additional height.

Having the radiant panels mounted at high level also reduces the risk of occupants being accidentally burned, so installations require no special consideration for young children or vulnerable occupants. This also provides advantages in potentially hostile environments, such as prisons.

Radiant heating typically costs less to install than conventional systems, because the radiant heating panels are usually installed at ceiling level, making pipe routing and installation less restricted. The reduced water content in the radiant panel system also requires less inhibitor chemicals, saving on installation and operational costs.

It is becoming increasingly common to use ‘free-hanging’ radiant panels, so removing the cost of separate ceiling systems. These have evolved into multi-service radiant panels(MSRPs) that integrate other building services – such as lighting, lighting control, and specific surfaces to reduce room reverberation time. Such systems are used to help meet the acoustic (described in Building Bulletin 935) and lighting (as per Lighting Guide 56) requirements for schools, while also delivering heating (as in Figure 5). MSRPs will be factory prefabricated, providing accelerated installation and improved quality control. They are well suited to restricted height projects, where finished soffit heights are relatively low – for example, 2.7m above floor level. The off-site prefabrication of MSRPs provides the quality assurance and manufacturing/procurement advantages of construction in a controlled factory environment. Factory assembly can reduce the project construction period, as MSRPs can be simultaneously assembled and tested while the building is constructed – so meeting ‘just in time’ programmes and reducing the need for skilled site workers.

© Tim Dwyer, 2014.

Further reading

A comprehensive text is Radiant Heating and Cooling

Handbook by Richard Watson, McGraw-Hill Professional,

2008, covering a range of areas, from fundament

References

- CIBSE Guide A, Section 5.6.2, 2006.

- Tredre, B., Assessment of mean radiant temperature

in indoor environments, British Journal of Industrial

Medicine, 1965. - Simone, A., et al, Operative temperature control of radiant

surface heating and cooling systems, Clima, 2007. - CIBSE Guide A, Section 1.5.6, 2006.

- Building Bulletin 93, Acoustic design of schools,

Department for Education and Skills. - Lighting guide 05, lighting for education (SLL LG5), CIBSE,

2011.